(MMC) to play key role in helping construction adapt to the NEW NORMAL

#constructionindustry #sustainable #architects #localauthorities #contractors #developers #innovation #buildingtechnology #mmc #cladding #newnormal #offsite #VUCA @Aquarian_Cladd

With the coronavirus pandemic affecting almost every industry, modern methods of construction (MMC) will play a key role in helping construction adapt to the ‘new normal’. Paul Richards, MD of brick cladding systems supplier Aquarian Cladding Systems, has seen the rise of MMC first-hand and explains why it will become even more important as the industry gets to grips with the ‘new normal.’

VUCA times (Volatility, Uncertainty, Complexity, and Ambiguity)

Technology and the use of data are hailed as the solution for most industry sectors to become safer, more predictable, and more profitable in increasingly volatile, uncertain, complex, and ambiguous (VUCA) times.

It could be argued that the construction industry has always experienced degrees of VUCA, but this time the case for the use of MMC as a solution is more compelling than ever, as it addresses the increasing number of challenges that we face.

Builders have always been under pressure to reduce construction costs and complete buildings on time. They must also consider the use of sustainable and thermally efficient materials. Having greater control over the construction process is vital and the controlled environment of offsite manufacturing or design and assembly of fewer components on site ticks most boxes.

MMC is not a ‘one size fits all’ solution and options vary from full turnkey, volumetric solutions to panellised or factory-assembled components – designed using the very latest visualisation and scheduling software technology. Key to the use of MMC is its ability not to compromise the appearance or performance of a building.

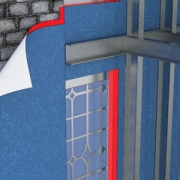

As brick facades seem more popular than ever in British architecture, so brick cladding systems are increasingly being used to give a building its traditional appearance and robust protection, with the advantage of being a modern method of construction.

We are experiencing greater demand than ever for our cladding solutions, as they offer all the benefits of an offsite solution but with the hybrid flexibility to be adapted on site too. Speed of delivery and installation, reduced build programmes and reduced prelim costs, including replacing scaffolding with mechanical access, are all major benefits of MMC.

Our brick cladding systems come in a wide choice of natural colours and finishes. Using brick slips formed from fired clay and pointed with natural mortar, a building will therefore still have a familiar, traditional appearance. Even tired looking buildings can benefit from a new lease of life, with negligible extra load and overall wall thickness.

Brick cladding systems are lightweight and versatile and therefore suitable for application either offsite or onsite. The reduced weight and support requirements mean reduced line loads, framing and foundations, with greater productivity and cost efficiency.

They are also more sustainable and will therefore reduce the environmental impact of conventional brickwork, due to the use of thin brick slips and less mortar. There is less material and embodied energy in production, fewer deliveries to site, reduced movement and storage on site, and less waste disposal.

Pedigree

Despite being classed as a modern method of construction, brick cladding systems are not quite as modern as many might think.

Our Gebrik system is a factory-produced, panelised alternative to conventional brickwork and is supplied in a kit of parts, including all components needed to create a brick façade. It has been produced since 1982 and so used across Europe for almost 40 years. Here in the UK, it has been used on buildings exposed to most extreme UK conditions including height, coastal conditions, and high pedestrian access.

Gebrik is fully tried, tested, and certified, and has been used on many award-winning projects throughout the UK and Europe. It’s BBA certified for application to most common substrates and has been successfully tested to CWCT test methods for weathertightness. It has also been fire tested on a number of occasions with different interfaces to BS8414 and on each occasion successfully met the BR135 ‘Pass’ criteria.

An ability to adapt

With Building Regulations changing across the UK, the only route to compliance for residential buildings above 18m is for the use of non-combustible, or limited combustible, i.e. A1 or A2, materials.

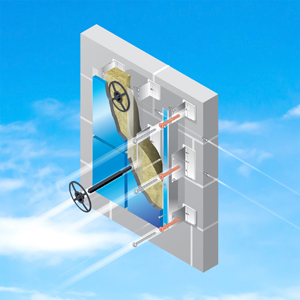

Our Mechslip and NaturAL-X brick cladding systems use brick ‘tiles’ with unique profiles to enable them to each be mechanically secured onto metal cladding support rails and subsequently pointed. Both systems have been tested to CWCT test methods for weathertightness and under EN13501, are classified as A1 so are suitable for use on buildings in excess of 18m (as well as those below).

For those wanting to minimise the risks associated with traditional construction, modern methods of construction such as brick cladding systems simply can’t be ignored.

Gebrik, Mechslip, NaturAL-X or Terreal have been used on many award-winning buildings across a wide range of sectors. Working with architects, contractors, developers and installation specialists, Aquarian’s team of cladding experts will provide the right solution, whatever the project.

www.aquariancladding.co.uk

variety of scope from the projects shows Totally Modulars commitment to the whole MMC journey, as the projects show a combination of accelerated housing delivery, digital planning and production technologies that will enable the industry to attain new levels of quality, variability, and efficiency.

variety of scope from the projects shows Totally Modulars commitment to the whole MMC journey, as the projects show a combination of accelerated housing delivery, digital planning and production technologies that will enable the industry to attain new levels of quality, variability, and efficiency.