Raising awareness of light steel frame technology

#construction #constructionindustry #sustainable #architects #localauthorities #contractors #developers #lightsteelframing #LSFA #offsite #buildingtechnology #fasteners @EJOTUKindustry

EJOT looks to fastening technology to build bridges within light steel framing

EJOT UK has recently chosen to join the newly launched Light Steel Framing Association (LSFA). The UK subsidiary of this global fastener manufacturing giant is not alone in making this strategic step, with several other manufacturing OEM’s and market leading system providers opting to make the same decision.

Since its inauguration a little over 12 months ago, the LSFA has set a clear objective to raise awareness of light steel frame technology across all building sectors, notably the exacting demands of offsite construction. Working closely with its members, the LSFA has set out its stall with a dedicated mandate to engage and educate the wider industry by highlighting the performance, productivity, and sustainability benefits light steel framing technology offers.

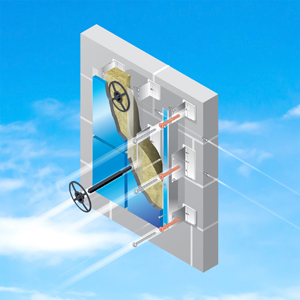

Historically, dedicated categories within EJOT’s traditional construction fixing portfolio have developed in tandem with light steel framing systems. As the latter have become an integral part of the modern building envelope – so EJOT has developed niche fastening solutions to satisfy growing market demands. For the fastener manufacturer, this has been most evident within application areas such as rainscreen and façade installation and external thermal render systems.

Utilising cross-sector expertise

However, the progressive development of offsite construction and its potentiality to the future of the industry is opening the door to utilise EJOT’s cross-sector expertise in order to capitalise on its engineering knowledge, worldwide research and development capability – all of which contributes to advanced fastening technologies that feed into applications that span virtually all assembly based products found in every corner of the globe. Unlike any other fastener manufacturer concerned with construction oriented products, this gives EJOT unique market positioning by bringing together products and expertise from the industrial and engineering sectors, thus utilising this fastening technology by integrating it into the products and installation techniques that we see on building sites today.

Whilst already an established sector, light steel framing can also be identified as one that will grow and develop to meet many future needs of an industry that is without doubt, going to face fresh challenges in balancing productivity against more focused legislation and the demands of an expectant local and global economy.

As one might expect, cross sector collaboration is not without its own cultural differences. EJOT’s traditional product range for the construction industry has in essence, evolved historically to provide high performance solutions for known on-site applications, delivered on time to where and when they are needed. It is a fast-moving flow of solutions and support.

In contrast, EJOT’s industrial engineering fastener capability worldwide is based upon a more long-term ethos of project development, managed side by side with customers. That often means modifying or re-engineering fastener thread, material – even coating technology – to arrive at a bespoke solution that delivers greater assembly and application performance efficiencies. So whilst the undeniable inevitability is that as original manufacturers of such a vast array of fastening applications across so many industrial sectors, the science of thread-forming, metallurgy and organic coatings, have cross-pollinated all of the sectors via a learning curve on all sides, not least what could equally be badged ‘the science of installation technology’.

Synergy with lightweight engineering assembly

EJOT’s application engineering team will tell you that the joining of different lightweight material compositions within engineering applications is as much to do with the measured precision of installation tools and techniques as the fastening products themselves – and it is here that synergy between EJOT’s overall expertise matches the potentiality of the light steel sector.

EJOT’s Technical Business Development Manager in the UK is Brian Mack:

“We are already seeing the adaptation and integration of highly technical industrial engineering processes into the planning and specifications for various modes of offsite construction and this will transform next generation building processes.

“As an example, we are finding increasingly that innovations developed for automotive assemblies are supporting the development of construction products and installation processes, with engineers on both sides of the fence now sharing common ground within joint project arenas”.

Such innovations in engineering technology include revolutionary fastening systems for vehicle frame assembly known as ‘body-in-white’. Such integration of products and installation programmes are now vastly contributing to the global need to ‘build lighter, build stronger’. Fully automated and semi-automated solutions developed in conjunction with industry partners such as the screwdriving specialist Deprag, are already proving to be pivotal in delivering an engineering-based approach to a rapidly developing construction sector.

Brian Mack continued:

“The development of cross-industry solutions via the origination of new technologies and products can support best practice and the progressive needs of light steel framing, especially within the MMC, volumetric and modular off-site sectors that we are already heavily involved with”.

Dedicated research, development and testing

Testing and technical support for the development of fastening products and installation systems is provided by the EJOT Applitec Centre which is based within the company’s UK manufacturing centre in North Yorkshire – with additional expertise provided by sister laboratories around the world. The investment made locally and internationally within all of these centres is evidence of the Group’s commitment to support the objectives and forward-thinking approach of institutions such as the LSFA.

Globally EJOT operates 15 manufacturing centres in ten countries, employing over 3,100 people. In addition to the manufacturing operations the Group has 34 subsidiaries in 32 countries, with six research and testing centres in strategic locations. EJOT has also developed partnerships with several academic institutions, aimed at maintaining the development of advanced fastening solutions for the future.

EJOT’s UK manufacturing centre is in Sherburn-in-Elmet, North Yorkshire. Visit the website or call 01977 687040.

Leave a Reply

Want to join the discussion?Feel free to contribute!