R for 3D BIM – GenieVision premieres smARt Viewer for construction at Digital Construction Week London

Benchmarking the on-site reality against the 3D BIM with one app

Charleroi, Belgium – GenieVision, a leading developer of AR construction technology, will showcase its smARt Viewer at the upcoming Digital Construction Week, 18-19 May 2022 at ExCeL, London. The GenieVision solution brings the BIM digital twin to life on site by means of an AR app on a mobile device, allowing users to detect, report, and fix construction flaws before they become major failures. On May 18th, 2022 at 12.30pm, François Snoeck, Product Manager at GenieVision, will host a presentation on the Tech Stage entitled “Can one smARt 3D BIM visualiser really get you those smart savings?”, during which he will illustrate how this innovative solution will save time and money for everyone involved in the construction process. Visitors who are not able to make it to his session will still have the opportunity to get a live demo in the GenieVision stand DC70 throughout the London Digital Construction Week.

App the BIM digital twin, build better buildings

In early 2018, GenieVision launched its smARt Viewer, an AR technology that visualises the 3D BIM on a portable screen in a way that goes well beyond just viewing plans. A 3D BIM brings together different dimensions of the BIM, creating a “digital twin” of the construction project. In the smARt Viewer app, users can compare the 3D model with the reality on site and spot, report, and correct errors, resulting in a drastic reduction of overall costs.

GenieVision’s multi-disciplinary team included experts in BIM, data, artificial intelligence, and gaming. This diverse group joined with construction partners, such as STRABAG, and Zublin collaborating on the application, resulting in real-world success as Frits Bonte, Digital Process Manager at STRABAG, indeed validates: “With the GenieVision smARt Viewer our site operators can verify the implementation and spot possible deviations quickly and easily. AR also lets users locate and visualise non-conformities more rapidly and communicate that visual information with other operators faster than previously possible. So far, we have successfully deployed AR in demolition work, structural works, and techniques. We are also planning to use it in renovations and maintenance as soon as we get the chance. It works.”

“By breaking down silos of information and connecting users across the entire project, our smARt Viewer improves quality assurance, streamlines building procedures, and delivers up to 50 percent savings on costs associated with construction failures,” says Philippe Carême, CEO of GenieVision. “We are looking forward to showing attendees of Digital Construction Week how our user-friendly, affordable, and best-in-class technology gets projects completed on time, on budget, and with fewer errors,” concludes Carême.

The proof of the app is in the demo

The GenieVision Product Manager, François Snoeck, will discuss how leveraging the 3D BIM digital twin will optimise overall construction operations for all parties involved.

Attendees of his presentation on May 18th at 12h30pm on the Tech Stage will learn:

- Why using AR for construction is the best way to benchmark your 3D BIM against the on-site reality and leverage it as a critical medium for quality inspection and technical due diligence on the worksite.

- How AR and a smARt Viewer turn data into a visual interface that prevents errors, improves collaboration, and saves everyone time and money.

- New ways of visualising the worksite environment so users can consult the data, spot the errors, report the comments, and fix the problems.

Visitors who would like to join his presentation can download a calendar invite by

CLICKING HERE:

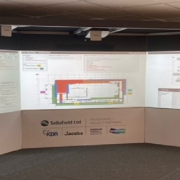

The BIM cave allows us to interrogate the design and look for potential conflicts, safety issues and scope review. It’s also a great visualisation tool for the team on site, as we can now work with them to catch issues with the design and show it on a larger scale rather than a single computer screen.

The BIM cave allows us to interrogate the design and look for potential conflicts, safety issues and scope review. It’s also a great visualisation tool for the team on site, as we can now work with them to catch issues with the design and show it on a larger scale rather than a single computer screen.