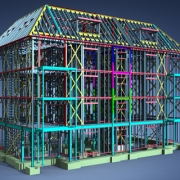

Recent years have ushered in a remarkable shift in the construction industry, driven by the evolution of off-site construction. This innovative approach to building structures marks a paradigm change, involving the creation of individual components in a controlled factory environment before they are transported to the construction site for assembly. The surge in off-site construction presents a host of advantages compared to traditional building methods, including heightened efficiency, cost-effectiveness, and an enhanced focus on sustainability.

The Momentum Behind Off-Site Construction:

The increasing momentum behind off-site construction originates from its exceptional capacity to streamline the building process. By fabricating components away from the construction site, projects can be completed at a remarkably accelerated pace in comparison to conventional methods. The controlled factory environment ensures superior precision and quality control, leading to a reduction in errors and the need for rework. Moreover, the simultaneous fabrication of components and on-site preparation significantly shortens the overall construction timeline. This accelerated process not only saves time but also minimizes disruptions to the local environment and communities. As a result, off-site construction has gained considerable traction across various sectors, such as residential, commercial, and healthcare, fundamentally reshaping architectural and construction practices.

Defining Off-Site Construction:

Off-site construction, also known as prefabricated or factory-built construction, is a pioneering technique that involves crafting building components away from the construction site, within a controlled factory setting. These components are then transported to the site and meticulously assembled to create a unified structure. The components are designed to fit together seamlessly, ensuring a swift and cohesive assembly process.

A central characteristic of off-site construction lies in the standardization and replication of components. Each component is meticulously crafted following standardized processes, ensuring uniform quality and dimensions. This standardized approach bolsters the efficiency of the manufacturing process, enabling large-scale production of components that can be duplicated across different projects. The components are meticulously designed to adhere to specific dimensions and specifications, enabling adaptability within the broader architectural design.

The Advantages of Off-Site Construction:

Off-site construction offers an array of benefits that make it an enticing option for a multitude of construction projects. Above all, it provides unparalleled cost-effectiveness. By harnessing the efficiency of factory production, off-site construction reduces labor costs and minimizes material wastage. It is an enticing selection for engineering and construction Chicago. The standardized procedures and repetitive nature of component manufacturing allow for economies of scale, translating to reduced overall project costs. This financial advantage makes off-site construction particularly appealing to cost-conscious clients and developers, empowering them to achieve their construction objectives while optimizing their financial resources.

Moreover, off-site construction offers an exceptional level of flexibility and adaptability. The use of standardized components facilitates easy customization and modification, enabling clients to tailor the design and layout of structures to meet specific requirements. Whether for residential, commercial, or industrial projects, off-site construction allows for efficient scalability and future expansion. This adaptability is especially advantageous for engineering firms in Chicago, empowering them to effectively respond to evolving client needs and market dynamics, while maintaining the highest standards of quality and precision.

In summary, the manifold benefits of off-site construction, spanning cost-effectiveness and adaptability, position it as a compelling choice for engineering firms in Chicago and beyond. Its capacity to deliver efficient, sustainable, and tailored architectural solutions establishes off-site construction as a leading force within the construction industry, redefining how projects are envisioned, executed, and brought to fruition.

Prioritizing Sustainability:

In an era where environmental sustainability is of paramount importance, off-site construction emerges as a solution deeply aligned with green building practices. This construction approach boasts an array of sustainable advantages that collectively contribute to reducing the ecological footprint. The controlled factory environment where components are crafted fosters optimized resource management. Through precise material calculations and minimized waste generation, off-site construction conserves valuable resources, including materials, water, and energy.

Furthermore, off-site construction facilitates the integration of sustainable technologies and practices. The standardized design and manufacturing process enable the incorporation of energy-efficient systems, such as renewable energy sources, smart building technologies, and energy-saving insulation. Additionally, the prefabrication of components within a factory setting reduces on-site disruptions and minimizes construction-related pollution, including noise and air pollution. The diminished need for transportation during construction further reduces carbon emissions.

Enhancing Safety and Efficiency Through Off-Site Construction:

Off-site construction, also known as prefabricated or modular construction, has proven to be an effective means of enhancing safety and efficiency in the building industry. One of the primary advantages of off-site construction is the controlled environment in which components are manufactured. This controlled setting minimizes the risk of accidents and injuries by eliminating common on-site hazards, such as adverse weather conditions and worksite accidents. Workers can operate in a safer environment, adhering to strict safety protocols and standards.

Furthermore, the prefabrication process in off-site construction allows for increased efficiency throughout the entire construction project. The simultaneous manufacturing of components and on-site site preparation significantly reduces the overall construction timeline. The components can be manufactured in parallel with site work, ensuring a streamlined construction schedule. This optimized workflow minimizes downtime and enhances productivity, resulting in quicker project completion. Moreover, the precision and quality control achieved in the factory setting reduce errors and rework, further enhancing efficiency and minimizing delays.

In Conclusion:

The ascent of off-site construction, underscored by its potential to elevate safety, optimize efficiency, and provide adaptable solutions, positions it as an enticing choice for an array of projects. From residential structures to commercial complexes, engineering firms in Chicago and beyond have embraced the promise encapsulated in off-site construction, harnessing its potential to meet evolving client needs while delivering top-tier, sustainable structures.

As the construction industry continues to embrace innovation, off-site construction stands as a testament to the transformative power of alternative construction methods. Its positive impact on timelines, budgets, and environmental considerations paves the way for an approach to architectural design and construction that is more streamlined, sustainable, and forward-looking.

Source: INSC

Ainslie McLaughin, Chair of the Edinburgh Home Demonstrator Programme Project Board, said:

Ainslie McLaughin, Chair of the Edinburgh Home Demonstrator Programme Project Board, said:

Polypipe Building Services Project Development Manager Graham Hicks said: “Our site visit revealed there were different layouts across the 91 flats, with some having a different bathroom configuration to others within the building which meant creating separate sets of drawings.

Polypipe Building Services Project Development Manager Graham Hicks said: “Our site visit revealed there were different layouts across the 91 flats, with some having a different bathroom configuration to others within the building which meant creating separate sets of drawings.