A £1m loan from Mayor Steve Rotheram’s Flexible Growth Fund has enabled pioneering local company Hemsec Manufacturing Ltd to open a new Structural Insulated Panel (SIP) Manufacturing Hub in Knowsley, creating 25 jobs and helping the city region’s drive to become net zero carbon by 2035.

Hemsec started out in St Helens in 1928 making cork cabinets to store ice for ice-cream makers. After decades of innovation, Hemsec were one of the UK’s first to develop structural insulated panels (“SIPs”) for residential applications at scale in 2007, foreseeing the UK’s need for more energy-efficient buildings, and for fast construction using modern methods of construction (MMC).

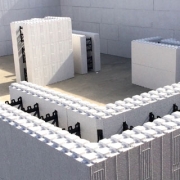

Panelised construction is a modern method of construction that involves the fabrication of structural panels off-site, which are then transported to the construction site for assembly.

Structural Insulated Panels (SIPs) provide a superior airtightness and insulation level, particularly in comparison to traditional masonry methods of building homes, producing homes that can significantly improve standards of living and are cheaper to heat.

Hemsec currently works with local housing associations on the development of low-carbon homes which can be built at speed and cost a fraction of price to heat, helping to appease the housing shortage whilst reducing energy bills significantly for occupants.

The £1m loan from the Flexible Growth Fund, the maximum amount available to a single applicant, has enabled Hemsec to create a new manufacturing hub in Huyton in Knowsley, creating 25 new jobs along with two apprenticeships for local people.

Speaking about the loan, Liverpool City Region Mayor Steve Rotheram, who recently officially opened the new plant, said:

“This is exactly what our Flexible Growth Fund was created for—empowering local companies to innovate, create jobs, and stay ahead in their field. Hemsec’s new manufacturing hub is not just an investment in their future but in the future of our region, driving forward our ambitions to be a leader in modern, energy efficient construction and helping us on our path to becoming a net zero city region by 2035.”

Cllr Mike Wharton, Cabinet Member for Business, Investment and Trade, said:

“The purpose of our Flexible Growth Fund is to provide fast and flexible loans to successful businesses to enable them to grow.

“Hemsec have long been pioneers in modern methods of construction and this loan will help them to stay at the forefront of this exciting sector and create jobs for local people in the process.”

Stephen Painter, Managing Director at Hemsec, said:

“The opening of Hemsec’s SIPs Manufacturing Hub represents a transformative moment for the Liverpool City Region and the British manufacturing industry. With the capabilities of this pioneering press machine, we have an unprecedented opportunity to accelerate the construction of much-needed truly affordable social housing, providing safe and sustainable homes for our communities.

“A fabric-first approach to sustainable buildings is crucial for ensuring the performance of our homes is optimised now and remains for the lifetime of the building, securing longevity in energy efficiency.”

The Flexible Growth Fund was established by the Liverpool City Region Combined Authority with £20m in 2020, offering flexible, low-interest loans that businesses can access quickly and easily, to enable projects to be completed.

Managed by River Capital, it is available to small and medium-size enterprises (SMEs) undertaking expansion projects and with the ability to raise 50% in match funding from the private sector.

All loans are paid back to the Combined Authority with interest, enabling the money to be reinvested in local businesses.