Bath and North East Somerset Council have announced a planning policy to reduce carbon emissions and work towards net-zero construction

This approach, in collaboration with the University of Bath, shows six initiatives aimed at achieving net-zero targets through local collaboration.

The report presented by the Key Cities Innovation Network (KCIN) in “Civic Partners in Net Zero“ sets an example of sustainable construction practices across the UK.

Achieving net zero by tackling construction pollution

Since January 2023, the Council has implemented strict local planning policies requiring that all new building developments achieve net zero operational energy. Major developments must also meet an incorporated carbon target, surpassing national building regulations. Bath and North East Somerset were the first UK local authorities to introduce these planning policies.

What happens in our cities – in construction, in transport, in waste processing, in energy consumption – has a major impact in how we reach our net zero targets as a nation

The council worked with the university to review the impact. So far, they found that initial assessments reveal a significant improvement in the projected outcomes of new applications, showing a promising shift towards eco-conscious construction practices. Industry support for the policy aims has been strong, showing a collective commitment to combatting climate change.

Professor Ian White, Vice-Chancellor of the University of Bath, praised the joint effort, highlighting sustainability as a priority research theme for the institution.

Initiatives across the UK

The “Civic Partners in Net Zero” report also features other initiatives from across the UK including:

- Coventry University and Coventry City Council’s new technology enables active recharging of electric vehicles, changing transportation in urban settings.

- Lancaster University’s collaboration with educators integrates sustainability into everyday teaching, inspiring future generations to embrace eco-friendly practices.

- Wrexham University allows communities and industries to drive the net zero transition, promoting a culture of environmental management.

- The University of South Wales explores the potential of biotechnology to support a circular economy by transforming waste into clean energy and fertilisers.

- The University of Southampton teams up with a theatre company to emotionally engage primary school audiences with climate science.

Cllr John Merry, Chair of Key Cities and Deputy Mayor of Salford City Council, said: “The ideas presented here are important and exciting. Important because what happens in our cities – in construction, in transport, in waste processing, in energy consumption – has a major impact in how we reach our net zero targets as a nation, and we in the Key Cities are determined to play our part. Exciting because they demonstrate the ingenuity in our universities and councils, and the strength of our growing civic partnership across the network. These are ideas we can build on, both as a network and in partnership with our communities, stakeholders and the government.”

Professor Maria Hinfelaar, Vice-Chancellor of Wrexham University, also highlighted the collective effort needed to replicate and upscale these initiatives.

Working towards net-zero-carbon construction

Cllr Kevin Guy, Leader of Bath & North East Somerset Council and Deputy Chair of Key Cities, said: “In Bath and North East Somerset, I am proud of the strong and longstanding partnerships we have with our two universities so it is great to see our collaboration with the University of Bath on net-zero-carbon construction so well reflected in the report.

Source: Open Access Government

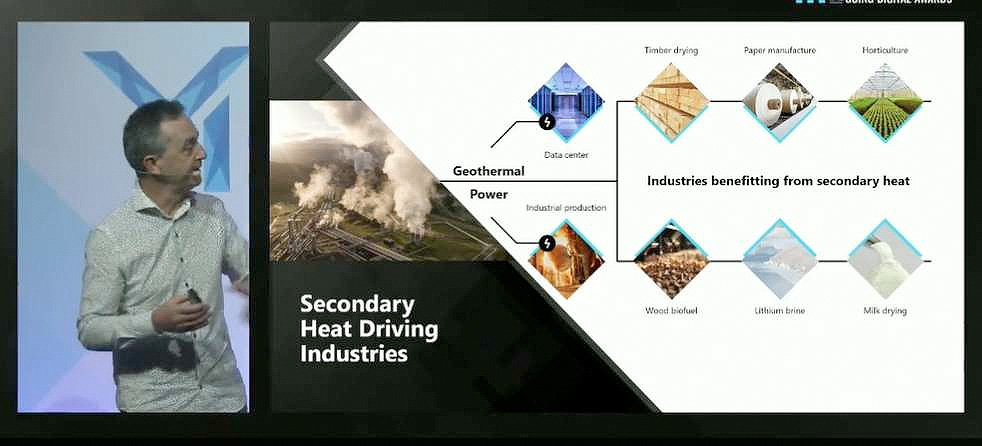

For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.

For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.