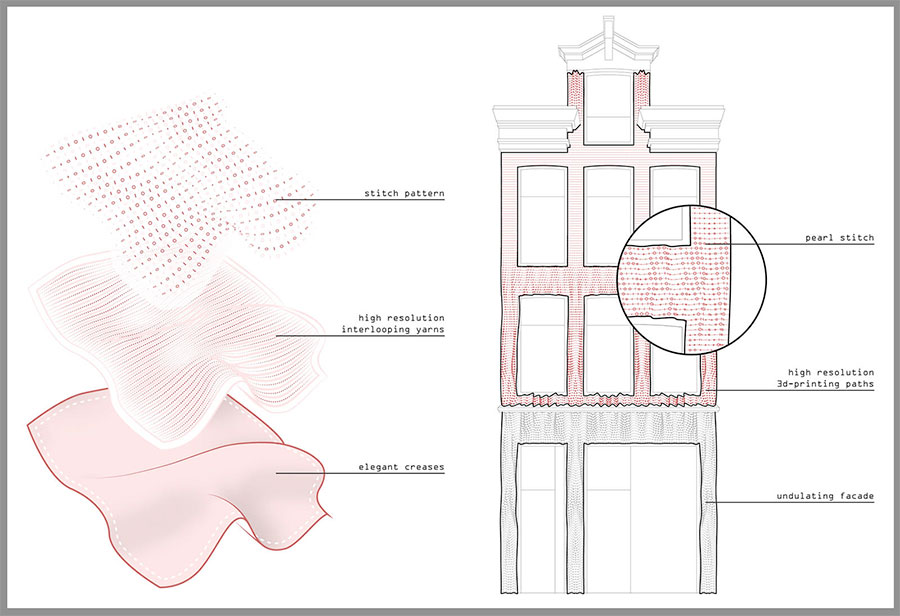

Elegant creases, interlooping yarns and stitch patterns; these are not just elements of a finely crafted garment but the poetic design language of Dutch design practice, the Studio RAP’s Ceramic House. In the world of architecture, the façade is the face of the building. Nestled in the heart of Amsterdam’s P.C. Hoofstraat, this boutique design transcends conventional norms and becomes a canvas, creating an organic, wave-like poetry. Far beyond a static exterior, this façade is a living testament to the delicate dance of form and function. It seamlessly blends tradition with innovation, not merely as a visual spectacle but as a tactile and immersive experience, inviting onlookers into a world where architecture becomes an art form.

In the genesis of the Ceramic House, the studio received a concise yet ambitious design brief from a client renowned for iconic architectural creations. Tasked with adorning Amsterdam’s shopping street with a unique boutique façade, the challenge was clear: conceive a retail design that transcends the ordinary. To meet this, the studio delved into the unexplored, seeking inspiration not from conventional architectural norms but from the world of knitwear.

The studio was in the midst of experimenting with 3D printing ceramic tiles for a previous project, New Delft Blue, when the idea of a façade entirely clad in 3D-printed ceramic tiles took shape. The result was the Ceramic House, an architectural masterpiece inspired by the artistry of knitting.

Amsterdam, with its cobbled stone streets and historic canals, is an architectural tapestry that weaves together the past and the present. Amidst this, the house stands as a distinct thread, weaving its own narrative. The key to the success of this project lies in its harmonious integration with the surroundings. Studio RAP meticulously replicated the silhouette of the original façade, maintaining the tripartite structure of the street. Expressive at ground level, the façade transforms as it ascends, synchronising with the surrounding structures. Architectural elements like rowlock arches and cross-bond brickwork echo the neighbouring buildings but with a contemporary twist. The connection of flushes between the new and adjacent facades, achieved through 3D scanning, showcases a commitment to precision, ensuring that the house stands as a luxury boutique seamlessly blending with its historical environment.

Digital design algorithms, a language of their own, become the brushes in Studio RAP’s hands. The Ceramic House explores the reinterpretation of glazed ceramics, infusing the historical city of Amsterdam with a new design vocabulary. The scale, size, type, and colour of the ornaments and materials are all carefully synced with the neighbouring buildings to allow a seamless integration of traditional and contemporary architecture. The façade’s intricate layers, inspired by textiles, mimic the elegance of creases and stitch patterns. An organic, wave-like quality unfolds as viewers approach, unveiling new elements within the bespoke 3D-printed ceramic tiles. This is not just architecture, it is a symphony of algorithmic design and historical resonance.

With inspiration drawn from the rich ceramic collection of the Rijksmuseum, the national museum of The Netherlands, the studio pioneers large-scale 3D printing technology. This isn’t merely printing tiles; it is an art form where architects collaborate seamlessly with advanced robotic systems. The result is highly differentiated and algorithmically designed details, showcasing a commitment to pushing the boundaries of architectural design.

The significance of using these innovative technologies lies in the studio’s vision to enrich the world with a new architectural language. Breaking barriers, they utilise 3D printing to gain unprecedented control over design, expression and precision. It is not just about industry digitisation; it is about preserving the cherished qualities of artisanal craftsmanship. Collaborating with Royal Tichelaar, one of the oldest companies in The Netherlands for ceramics and glazes, adds a touch of tradition to this technological partnership.

At street level, the house beckons with large 3D-printed ceramic tiles glazed in pearl white, subtly touched with yellow by Royal Tichelaar. Visually expressive at eye level, these tiles transition gracefully to a flush alignment with the ground, creating a harmonious aesthetic. Ascending higher, the façade unfolds another layer, showcasing 3D-printed bricks glazed in three shades of red. The abstract ornamentation dances with the original masonry cross bond, housed within the laser-cut stainless-steel cassettes, a nod to historical flushes.

For Studio RAP, 3D printing and algorithmic design aren’t just tools; they are the essence of the Ceramic House’s identity. Drawing inspiration from the art of knitwear, these strategies amplify the intricate layers of the façade design. There is a fascinating parallel between traditional knitting patterns and the tiles; both following conceptual instructions. The result is what the studio calls the “pearl-stitch”, a unique architectural expression merging historical ceramics with the allure of knitwear-inspired details. It is not just a building, it is a conversation between traditional architecture and the avant-garde.

As visitors approach the Ceramic House, a layered experience unfolds. From a distance, it seamlessly blends with the legacy of the street. Come closer, the undulating façade sparks curiosity, and the pearl stitch pattern emerges. Opening the door is an invitation to feel the texture, a tactile exploration of bespoke details. Each unique tile ensures that every visit unveils a new detail, creating a timeless and layered experience. It is not just a façade; it is an immersive journey through layers of innovation and tradition.

The Ceramic House isn’t an isolated project; it is a concrete manifestation of Studio RAP’s broader vision. Situated in Rotterdam, the team redefines the traditional role of architects. They aren’t just architects, they are entrepreneurs, craftsmen and innovators. The studio challenges conventions, injecting greater excitement and diversity into the world through innovative design.

In the words of the studio, “The Ceramic House project reshapes architectural expression by seamlessly blending tradition and innovation, reintroducing bespoke details to architecture. It’s more reshaping; it’s a revolution that challenges the status quo and presents a fresh architectural style. The project is a testament to the Studio RAP’s commitment to infuse the world with greater excitement and diversity through architectural innovation.”

Studio RAP isn’t just an architectural design company; it is a harbinger of change, challenging conventional ways of building. With architects, designers, roboticists, programmers and researchers collaborating in an industrial atmosphere surrounded by robots in Rotterdam, the studio embarks on a hands-on approach to solving problems in the building industry. Studio RAP doesn’t just create expressive buildings, it reimagines the entire architectural profession, embracing innovation as the cornerstone of its practice.

The Ceramic House stands not just as a building but as a testament to the marriage of tradition and innovation. As we trace the undulating façade and feel the tactile allure of each bespoke tile, we are invited into a realm where architecture becomes an immersive journey. Beyond its physical form, the house embodies a question: What other uncharted territories can façade design explore? Studio RAP’s revolution extends beyond a single, prompting us to ponder the possibilities that lie ahead in the dynamic tapestry of architectural innovation.

Source: Stir