Image Credit: NBS

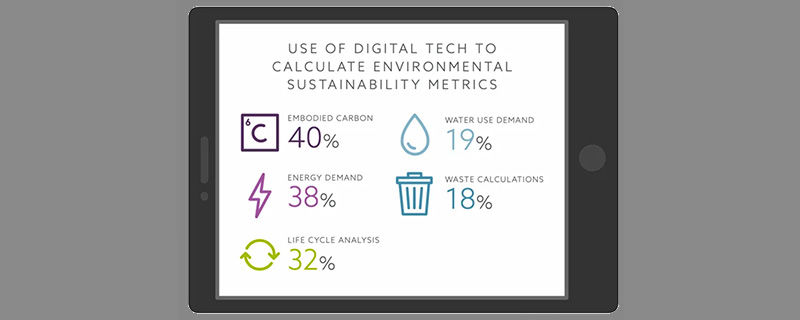

Today, NBS, the platform for connected construction information, reveals the results of its Digital Construction Report. The study explores the industry’s evolving relationship between digital technology and safety and sustainability – the sector’s biggest challenges. This year it showed two-thirds of professionals using digital tools to calculate environmental-related metrics, a sign that sustainable design is now intrinsic to construction processes.

Significantly, four in ten use digital methods to understand the embodied carbon attached to a project – that is, the amount of CO2 emitted during construction. A similar figure (38%) also uses it to quantify the energy demands of structures and the components that go into them. There’s room for improvement, but the figures show a clear push towards lower carbon outcomes.

Off-Site on the Up

Continuing with the theme of sustainable construction, NBS also analysed levels of off-site construction, an area often associated with greener building practices, due to greater control of materials and waste. The results found that MMC (Modern Methods of Construction) continues to gather pace.

Over half of professionals (57%) had been part of a construction project that had used or required off-site construction within the last year. This is an increase of 7% since 2021. This news comes despite the closure of several high-profile MMC factories.

Delving deeper, manufacturers are the group most likely to be involved with MMC – 7 in 10 had worked with an off-site element, followed by nearly two-thirds of contractors (63%) and over half of consultants (58%). This increase could reflect an industry drive towards net zero as well as recent government backing for further standardisation within MMC.

Living in the Cloud

The report also found that cloud computing is becoming further embedded within building practices, with four out of five now using it.

The stats highlight the positive way technology is supporting collaborative working, with three-quarters using it to share documents and information with clients (77%). A similar number (74%) use it to collaborate with team members and produce 3D models, specifications, and other important documents.

Taking Full Responsibility

NBS’ Digital Construction Report also highlighted increases in the number of professionals following naming conventions when sharing information (77%, up from 2021 figures) – an area that can improve the organisation and management of data. Additionally, over half of respondents reported using interoperable formats like IFC, revealing the growing importance of easily shareable construction data.

However, the report also showed that there are more opportunities to be unlocked by using digital technologies to help with compliance.

The study found that only a third of respondents (34%) were involved with detailed responsibility matrixes (DRM), a process that sets out responsibility for each element of design to ensure greater accountability. Worryingly, this figure has dropped since 2021 (39%). Notably, this figure hovered at around half for architects. This comes despite increased levels of legislation attached to the Building Safety Act, such as the introduction of planning ‘gateways’ which requires a detailed breakdown of responsibilities on an individual level.

Additionally, less than a third of suppliers (28%) currently use a PIM system to manage product information, pointing to information gaps in the construction supply chain. Nevertheless, well over half (56%) provide digital objects for the majority or all their products, a positive result.

Commenting on the survey’s results, David Bain, NBS’ Research Manager, said, “The uptick in professionals seeking environmental-related metrics shows an industry putting sustainability front and centre. The drive towards Net-Zero has no doubt been a catalyst alongside the evolving legislative landscape – there’s never been a greater emphasis on the environmental impact of building practices.

“The study has also yielded unexpectedly positive stats around off-site construction. Despite media headlines and high-profile factory closures giving the impression that MMC isn’t a popular choice, the results show a different story: more professionals are embracing off-site elements than ever before.

“Overall, we’ve seen some marked improvements that the industry should be proud of. There’s an opportunity here to improve digital information sharing, for which professionals have a legal requirement. The ‘golden thread’ and the use of structured data is creating a safer future for all.”

Click here for the full report

Leave a Reply

Want to join the discussion?Feel free to contribute!