Plastic is bad right? Yet, low maintenance, thermally efficient and highly recyclable, on paper it has a lot to offer the construction sector. So where is it going wrong?

You’re on site. It’s a muddy winter’s day and bundles of shrink wrap and tape are blowing like tumble weed in a Western movie, across the muddy puddles, waiting to entangle themselves in neighbouring hedgerows. It’s as negative an image of plastic as there can be (unless its ensnaring marine wildlife). And while the construction sector has taken steps in the right direction, plastic waste remains a big problem. Recent government data shows that the UK has cut plastic waste by 2.7% over the past two years as we switch to paper straws and reusable bags. But at the same time plastic waste in construction jumped by 46%, reflecting increased sector activity.

So, can plastic ever be green? Or should the construction sector be turning its back on it once and for all?

“Plastic waste is definitely a problem for construction”, says John Duckworth, Director Commercial Sales, Deceuninck. “Site waste can be massively damaging.

“But the issue is less about the material than our attitude towards it. If we stop seeing plastic as disposable, the problem goes away.” This is the point of contention for Deceuninck, the PVC-U window systems leader. It has invested more than €15million in one of the world’s most advanced recycling and compounding facilities to create the capacity to reprocess up to 45,000 tonnes of post-consumer and post-manufacturing PVC-U per year. In real terms this gives it the capacity to prevent more than three million windows from going to landfill annually. “It’s about the circular economy”, continues John. “Manufacturing products with less embodied carbon; designing them better so that they are more energy efficient; and making them easier to recycle at end of life. “It’s about lowering carbon and to do that we need to change our approach to material choices.”

Deceuninck’s recycling facility also encompasses the largest dry blending facility in Europe, fully integrated with its main manufacturing facility, the approach connects process, while reducing CO2 emissions by 90,000 tonnes compared to virgin feedstocks. It also delivers a 90% energy saving.

This forms a key pillar of Deceuninck’s commitment to ambitious targets to reduce greenhouse emissions through the corporate carbon reduction scheme, Science Based Targets (SBTi).

This includes the pledge to cut the CO2 emissions from its own operations (Scope 1&2) by 60% by 2030 from a 2021 baseline. Allowing for future growth in real terms this means reducing CO2 per tonne of product produced by 75%. This goes significantly beyond the SBTi minimum target of 42%. It has also committed to cut emissions from within its supply chain (Scope 3 emissions) by 48% per tonne by 2030, as part of its wider journey to net-zero greenhouse gas emissions by 2050. John continues: “In the UK PVC-U has an A+ Green Guide Rating on the basis that it can be recycled more than 10 times, without impacting on performance. “PVC-U windows have a reference service life of around 35 to 40 years, so the material used in each window made with virgin feedstock could be recycled and still be in use in 350 to 400 years’ time.

“The key thing is we have to recycle it.”

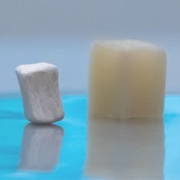

Deceuninck’s main suite of energy efficient window and door profiles can include up to 50% recycled material. This is manufactured using leading edge co-extrusion technologies, which isolate recycled content in areas away from the surface of the product, guaranteeing finish and performance.

Deceuninck’s main suite of energy efficient window and door profiles can include up to 50% recycled material. This is manufactured using leading edge co-extrusion technologies, which isolate recycled content in areas away from the surface of the product, guaranteeing finish and performance.

“The technology is there today to manufacture a 100% recycled window”, John continues, “We’ve done it with Phoenix, our 100% recycled window. “In bringing post-consumer material back into use on a day-to-day basis at a lower level, we’re already lowering the carbon footprint of our products but critically, designing them to be easier to recycle at end of life, pushing down the carbon footprint of the next generation of products.”

Elegant is one of a new generation of energy efficient window and door systems from Deceuninck. The fiberglass composite window delivers a step change in performance achieving U-values as low as 0.8W/m2K. The system is built around a single ultra-energy-efficient modular frame which is available as a standard 76mm system. These can be combined with any of five different sash options.

It can also be combined with Decoroc, Deceuninck’s next generation foil, so fitted alongside aluminium products as part of dual-specification installations.

“Elegant gives you a lot of design flexibility,” John says. “You’re getting a window that can be optimised for either commercial or residential applications with a massive amount of flexibility within those markets because of the combination of sash and frame options that we can offer.”

Given this combination of design, flexibility, advanced thermal performance and recyclability at end of life, John argues that PVC-U building products continue to offer significant value to the construction sector – but moreover, can be part of a greener future.

“We maybe need to get over one or two prejudices that we have about materials and to judge them on what they actually deliver”, he says. “There are underlying issues about our attitude towards plastics but much of that sits with our cultural attitude towards them and the fact that we have seen them as being disposable. “If you’re judging PVC-U as a building material and PVC-U windows and doors within that category, you should be approaching that process factually. “The material is energy efficient, it can and is being recycled and new generation composite PVC-U products can and are being used to maximise value on a wide range of projects.”

For more information call 01249 816 969

CLICK HERE to email Deceuninck

CLICK HERE TO VISIT THE DECEUNINCK WEBSITE

Leave a Reply

Want to join the discussion?Feel free to contribute!