AIM – Acoustic & Insulation Manufacturing Fire Stop Blocks are now backed by test evidence covering a wider range of applications. Tested to the principles of BS EN 1366-4:2021, AIM’s Fire Stop Blocks also have IFC Certification Ltd third-party certification.

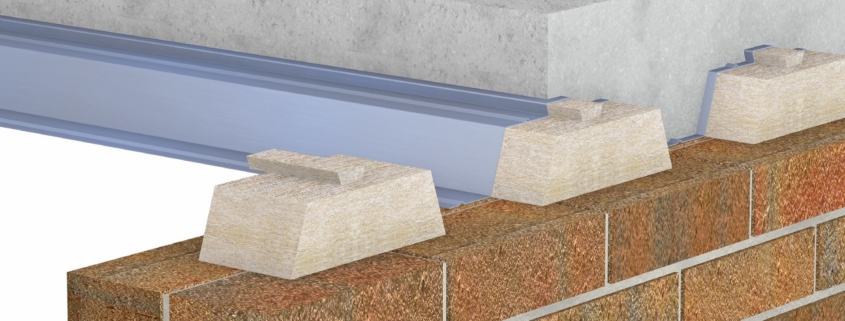

Made from high density stonewool, AIM Fire Stop Blocks are incorporated into multi storey buildings during construction to seal apertures. They are used where the underside of a profiled metal sheet, typically a composite deck, needs to be filled to prevent the passage of smoke and fire to maintain fire compartment lines and to reduce the transmission of sound.

“At AIM we continuously strive to improve our product certification. We now have test evidence covering a much wider range than previously – we think the widest of all fire stop block manufacturers,” explains Ian Exall, AIM’s Commercial Director.

“Our Fire Stop Block range is comprehensive. Additionally, our CNC machine can manufacture Fire Stop Blocks to pretty much any profile,” he adds.

Available in lengths up to 1200mm or in shorter pre-cut blocks, AIM’s Fire Stop Blocks are designed to fill the flutes of trapezoidal formwork. With its CNC wire saw capability AIM manufactures Fire Stop Blocks to almost any profile or customer’s dimensions. The CNC cut provides ultimate accuracy especially for profiles with rounded shoulders.

For maximum protection, Fire Stop Blocks should be sourced at a length to match the width of the wall or partition. The compression fit means mastics and sealants are not required for most applications and the Fire Stop Blocks are easy to install without tools. If the head of a masonry wall is rough, then a metal ‘slip plate’ can be used to provide a smooth surface for the Fire Stop Block to slide across.

Ablative/pre-painted Fire Stop Blocks are also available if required, these should be sealed around their perimeter using AIM Acrylic Intumescent Mastic.

AIM’s 100mm Fire Stop Blocks provide a one-hour integrity and insulation fire rating whilst the 125mm solution provides a two-hour integrity and insulation fire rating. The ratings are supported by testing to BS EN 1366-4:2021, which provide a specific methodology for ‘testing fire stops installed into permanent trapezoidal formwork’. Tata Steel’s C19, CF80 and CF225 profiles were used in the testing programme – direct field of application that covers most profiled metal decking available in the current market.

Ablative Fire Stop Blocks, sealed with AIM Intumescent Mastic, have also been tested for applications where air tightness and general aesthetics are more important.

The tested profiles are now supported by third party certification from UKAS accredited IFC Certification Ltd, a process involving independent auditors which ensures the product that had been fire tested is the product that is sold to market and the finished product is manufactured to consistently high standards. Regular audits ensure the standards of production are maintained.

A new AIM Fire Stop Block technical datasheet, which explains the application, scope of test evidence and fixing instructions, is available to download at: https://www.aimlimited.co.uk/solutions/fire-stop-blocks-2/

AIM’s specification team is on hand to advise specifiers, fire consultants/engineers, metal deck system holders and installers, including cladding and bricklaying contractors, dryliners and fire protection contractors.

Part of the Performance Technology Group, UK-based Acoustic & Insulation Manufacturing has over 30 years-experience in the design, testing and manufacturing of high-quality fire, thermal and acoustic barriers. The company produces a wide variety of bespoke insulation products to customer specification and a range of standard fire, thermal and acoustic insulation products.

Leave a Reply

Want to join the discussion?Feel free to contribute!