In recent years, there has been a growing focus on the impact of embodied carbon in all areas of construction, with the Environment Audit Committee calling for the Government to introduce mandatory whole life carbon assessments for all buildings¹.

Whilst addressing this area will be key to achieving the country’s Net Zero ambitions, it is important that project teams understand the relationship between embodied and operational carbon emissions. In some cases, changes to specifications designed to reduce embodied carbon emissions, can notably increase operational emissions. This is especially true when it comes to insulation for building fabric and services. New calculation tools are now available which can help specifiers to balance these objectives and achieve an optimal outcome.

Understanding Insulation Emissions

Phenolic pipe insulation products are a popular solution for both on- and offsite building services specifications. A key reason for this is their thermal conductivity, which can be as low as 0.025 W/mK. The lower this value is, the more effective the insulation is at preventing heat transfer. This means building services are able to perform more efficiently (with lower operational carbon emissions) at a given thickness of insulation when compared with insulation materials with higher thermal conductivities, such as mineral fibre. As with all insulation materials, when specifying phenolic pipe insulation, it is possible to further reduce heat transfer by using greater thicknesses of insulation. However, this will also raise the embodied impact of the product as greater quantities of raw materials must be used, produced and transported to insulate a given length of pipework.

It is important to have a clear understanding of this trade off in order to minimise a building’s overall carbon emissions. In the case of pipe insulation, properly installed measures will deliver operational carbon savings across a building’s lifespan. This means that whilst increases in insulation thickness will marginally raise embodied carbon emissions, the savings in operational carbon emissions will typically be much greater.

Carbon Calculator

To support project teams, the Kingspan Kooltherm Pipe Insulation Carbon Calculator tool has now been launched. The tool is designed to be quick and easy to use, helping

specifiers to gain a better understanding of operational and embodied carbon emissions, along with the payback period for the specified insulation.

Users need to enter a few project conditions, such as energy price and operational hours, along with factors specific to the system design including pipe lengths, diameters and materials, and system operational temperatures. The calculator will then generate results for different pipe insulation thicknesses based on the following key industry standards:

BS 5422 – this sets out minimum insulation thicknesses for a range of systems and scenarios;

Energy Technology List (ETL) – this provides enhanced pipe insulation specifications designed to raise system performance;

CIBSE CP1 Heat Networks – Code of Practice – this includes recommended thicknesses for internal building pipework used as part of heat networks.

There is also an option to input your own custom thicknesses of Kingspan Kooltherm Pipe Insulation to see how these may impact results.

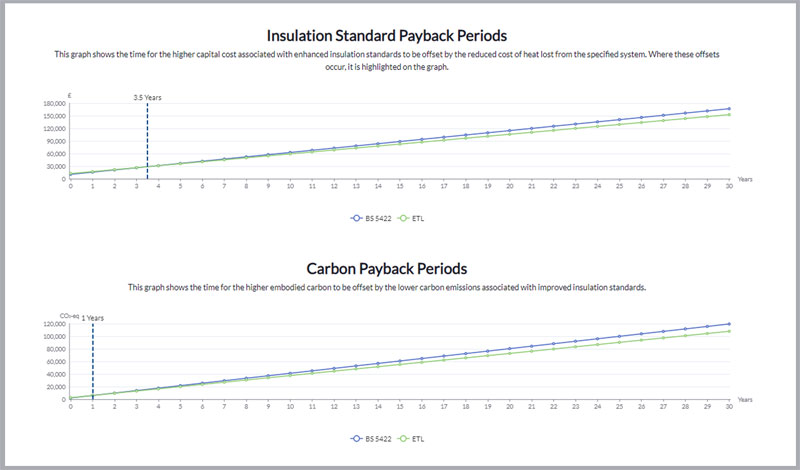

The tool provides a range of outputs in clear graphs. The embodied carbon of the relevant size and thickness of insulation will be calculated, and this will be combined with the carbon associated with the lost heat over a specified period of time.

You will also receive the results for system heat loss on an annual basis, the costs associated with these losses along with the expected capital cost of the insulation product (not including installation, pipework or other fittings).

As shown below, the graphs are designed to allow different specifications based on the three industry standards, or those from custom pipe insulation thicknesses, to be easily compared. This can help to understand the time it will take for the additional capital cost and embodied carbon from enhanced specifications to be offset by the reduction in the carbon from lost heat and associated costs. These results can then be generated into a project specific report.

If you would like more information on our new tool and how it can help your project,

PLEASE CLICK HERE TO EMAIL

Kingspan Technical Insulation’s team

CLICK HERE TO VISIT THE KINGSPAN WEBSITE

1. LINK

Leave a Reply

Want to join the discussion?Feel free to contribute!