Suchit Punnose, Founder and CEO of Red Ribbon Asset Management on the new frontier for housing set to transform emerging markets.

Modular construction as a concept goes back a long way. A really long way. Its origins date back to the 17th century when colonial Americans wanted their homes built in England. So they were. The disassembled house was shipped across the Atlantic and reconstructed in America.

Fast forward to today, and modular construction is on the cusp of a housing revolution. The growing realisation that modular construction is the answer for environmentally- and budget-friendly housing is changing developer and investor attitudes. This, combined with the disruptive innovation shaking up the 21st century, is propelling modular housing forward as a solution to the housing problem.

Disruptive innovation + modular construction – a solution to the housing crisis?

The most successful business models of our time – Amazon, Google, Uber – have completely disrupted previously solid markets. And the outcome is a radical shift of the way we live, work and function.

These businesses are successful because they began with a disruptive premise. They continued through market scepticism and took the time to cultivate a change in consumer mindset. Disruptive innovation is driven by invention and market demands. When it comes to housing, there is an urgent need for affordable but high-quality residential units around the world.

Modular construction at scale is the answer. Red Ribbon’s Modulex Global is an example of advanced, modern modular building technology. High quality, carbon-neutral and smart homes can be constructed off-site to provide a solution to the global housing crisis.

Changing developer and investor mindsets

As cities continue to grow exponentially, so do the numbers of people lacking housing. According to Yale University, national reports suggest that more than 150 million people around the world are homeless. The relentless trend of urbanisation underlines the inefficiency of the housing market in both developed and emerging economies.

Statistics from the UN show that:

- Between 1950 and 2018, the number of people living in urban areas increased from 751 million to 4.2 billion (more than half of the entire population).

- By 2050, this figure will rise to around 68%.

- This will be mostly in the developing and emerging economies.

- We will see extremely high rates of urban expansion in the Middle East, across Asia, and sub-Saharan Africa.

- India, China and Nigeria will account for more than third of urban population growth between now and 2050.

In light of rising homelessness, attitudes towards modular housing are changing. According to US consultants McKinsey, more than 80% of developers are committed at some level to modular construction models. The lower cost, higher quality at-speed housing solution makes the most commercial and practical sense for a better housing future.

Access to adequate housing is the basis for a successful economy

Access to affordable housing, anywhere in the world, is the foundation of a working society and economy. And while what is considered ‘affordable’ varies from country to country, the broad idea that housing should meet certain parameters is accepted everywhere.

Housing should offer security, privacy, structural safety, access to water, heating, electricity and sanitation. It also needs situating near to amenities such as the workplace and hospitals. Data from McKinsey shows that an estimated 330 million households around the world have no access to quality, affordable housing. If major steps are not taken, this could increase to 440 million over the next five years.

The housing challenge is felt the most in emerging economies and cities that have high levels of substandard housing. Investment in truly affordable construction is still far too low in emerging markets. Developers and construction companies use outmoded tech and remain increasingly focused on high-value projects that encourage a culture of inefficiency.

Changing the mindset of developers is key so that they focus on affordable, mid-market housing projects on a massive scale. In India alone, around 1.77 million people are desperately in need of housing despite the work being done by the Government’s Affordable Housing Programme.

An innovative solution to a growing problem

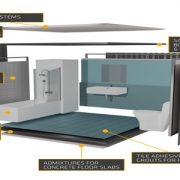

The smarter, more efficient technology contained in modular construction is the clear answer to the global housing crisis. Units fabricated off-site are delivered in ready-to-build panels and fitted together. Modular units can be built in a controlled environment, resulting in higher quality standards along with lower waste levels and costs.

We established Modulex to harness the constantly evolving technology to deliver housing projects at a third of the traditional cost. Establishing the world’s biggest steel modular building factory in India is a major step towards fundamentally disrupting the housing construction market.

If every residential building project in India used modular housing, they would be completed faster, at a lower cost and with reduced carbon emissions. And while we’re focusing primarily on emerging markets for now, there is also huge potential for modular housing in the UK and Europe. het.

Founded in 2007, Red Ribbon Asset Management Plc (‘Red Ribbon’) is an Indo-British financial services group building on the legacy of historical, cultural and socio-economic ties between the two countries. As India’s global economic role has burgeoned and it looks to a golden decade of growth – following the pattern of China’s trajectory template 20 years ago – the UK is shifting into a post-Brexit phase where trading and commercial relationships outside the EU are coming to the fore.

Source: Enterprise Times

Follow us on Twitter

Follow us on Twitter

Join us on Linked in