By Carl Davison Technical Services Manager at Kingspan Industrial Insulation.

Thermal comfort has become the focus of increasing attention in recent years as designers and project teams look to create a healthier built environment. Whilst the enhanced thermal performance and airtightness provided by some offsite envelope solutions can help to make indoor conditions more easily controllable, careful attention must also be paid to potential heat sources within a space which can lead to overheating. Research from AECOM has now shown that pipe insulation specification can have a major bearing on how easily properties overheat, as well as on their overall energy demand.

Requirements

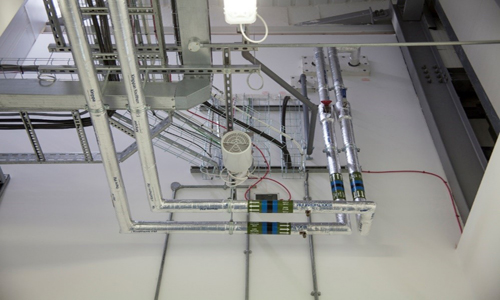

The minimum insulation requirements when specifying hot water and heating systems are contained within the Domestic and Non-domestic Building Service Compliance Guides1. For optimal system efficiency, however, the Energy Technology List (ETL) recommends a higher performance pipe insulation specification based on NES Y50 Enhanced levels.

A wide range of pipe insulation options are now available and a key differentiator between these is their thermal conductivity. Insulation materials with a lower thermal conductivity are more effective at preventing heat transfer through conduction, meaning a reduced thickness can be used to achieve the desired level of insulating performance. Premium phenolic pipe insulants are amongst the most thermally efficient options, with a 25-year aged thermal conductivity as low as 0.025 W/m·K (at 10°C mean), and are available with phenolic insulation pipe supports to further minimise heat losses.

Research

To investigate how these different specifications can affect overheating and system performance, AECOM carried out a detailed evaluation using IES dynamic thermal modelling. The research assessed the performance of three insulation systems on LTHW (Low Temperature Hot Water) and DHW (Domestic Hot Water) pipework, within a multi-unit residential extra-care building with a constant circulation of hot water:

1 Man Made Mineral Fibre (MMMF) Pipe insulation specified to BS 5422: 2009 with rubber lined pipe support brackets.

2 Phenolic pipe insulation specified to minimum standards within BS 5422: 2009 with phenolic insulation pipe support inserts.

3 Phenolic pipe insulation to the enhanced

ETL specification with phenolic insulation pipe support inserts.

The study also considered the use of extraction fans to dissipate heat.

Results

To evaluate the impact of each specification on overheating, AECOM calculated the percentage of hours with a dry resultant temperature of greater than 25°C2 and 28°C3.

The results showed that, when compared with the MMMF system, the BS 5422 phenolic specification provided a reduction of up to 15% in overheating hours at a room temperature greater than 28°C, and up to 9% at a room temperature greater than 25°C. The ETL specification offered significant further benefits with falls of up to 32% in overheating hours greater than 28°C, and 25% in overheating hours over 25°C.

In some scenarios, the modelling showed that rooms with the MMMF specification would have experienced over 100 additional hours at temperatures above 28ºC when compared to the ETL specification.

These reductions also produced considerable energy cost savings. The projected average energy cost of the MMMF specification was calculated at £3,973, rising to £4,105 when the impact of additional extraction fans was considered. The BS 5422 phenolic specification achieved annual savings of £431 or £463 depending on whether the impact of extraction fans was taken into account. With the ETL phenolic specification even greater savings of £1,252 and £1,384 could be achieved.

Finally, the study showed that when the extract fans were considered, the ETL specification would have an immediate payback.

In control

The move towards a healthier, more energy efficient built environment requires project teams to think more holistically about how all of the elements will interact. As the AECOM research shows, by paying close attention to areas such as pipe insulation specification, it is possible to achieve considerable reductions in both energy demand and overheating hours.

www.kingspanindustrialinsulation.com

1 This expands on the specifications within BS 5422: 2009 (Method for specifying thermal insulating materials for pipes, tanks, vessels, ductwork and equipment operating within the temperature range -40°C to +700°C)

2 The recommended acceptable indoor design operative temperature within CIBSE Guide A 2006

3 The preferred maximum temperature for thermal comfort

Leave a Reply

Want to join the discussion?Feel free to contribute!