Structures that utilize both panelized and modular construction are known as hybrid systems, and they provide owners and designers with the ultimate range of flexibility

To reap all the benefits of hybrid construction systems, designers and builders make deliberate choices about which approach is used for each component of the structure. The most important benefit of hybrid off-site construction is that it recaptures some of the flexibility associated with traditional, stick-built construction without giving up the environmental, economic, or quality benefits of off-site construction.

Challenges and constraints must be addressed by architects and engineers early in the design phase of a project. Manufacturing and transportation constraints are major variables to consider, as they immediately limit construction options. Designers must know in advance where the panels or modules will be fabricated, each facility’s production size limitations, and what the transportation constraints are for shipping the panels to the site. Hybridized construction enables designers to address this broad range of constraints through a greater number of potential suppliers, which provides more manufacturing and transportation options to meet the architectural and engineering requirements for each project.

There are also advantages to be realized at the building site. Perhaps most importantly, the finishes in the structure’s high-value areas can be completed at the factory and shipped to the site in a weather-proof module. Integration is the key to successfully designing and constructing a building that will employ multiple off-site construction methods. It is also the biggest challenge. Volumetric modules and panels must connect within strict tolerances for the design to be realized, so it’s critical that all stakeholders work from a shared set of plans.

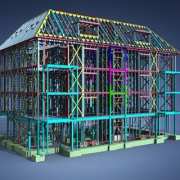

Vertex Systems created Vertex BD, a building information modeling (BIM) software platform, specifically to handle complex design scenarios of this nature. The platform automates design and manufacturing processes for all the prefabricated components that will be built and shipped to the job site. The software also translates essential project information across all the disciplines involved in producing each module. Manufacturing data, plans, schedules, and material reports can be automatically created within the platform and shared with contractors and suppliers to ensure tight coordination across the project.

3D visualization tools are immensely important for hybrid projects because they allow designers, owners, and builders to see how the 3D modules and panels will come together and how all the critical connections will be formed. Vertex BD includes powerful 3D visualization tools that allow designers to perfect the design and address any glitches early in the design process.