Rothoblaas solutions for prefabrication

In the world of timber construction, the ability to preassemble part of the construction elements facilitates construction site work both in terms of speed and in terms of waste management; as a result, it improves the operators’ quality of life.

The choice of a supplier, therefore, will be based primarily on the availability of materials suitable for pre-fitting.

Rothoblaas membranes, along with other sealing and insulating products, are not specifically designed to be preassembled, but being useful in a prefabrication context is their inherent characteristic.

Rothoblaas self-adhesive membranes

The advantages of high-performance adhesives and application contexts Installing a self-adhesive membrane is simple and intuitive, but the application context and the adhesive’s performance, can make all the difference. Consider the need to waterproof Mass Timber panels that will form the framework of a timber building. The application context of the membrane makes all the difference.

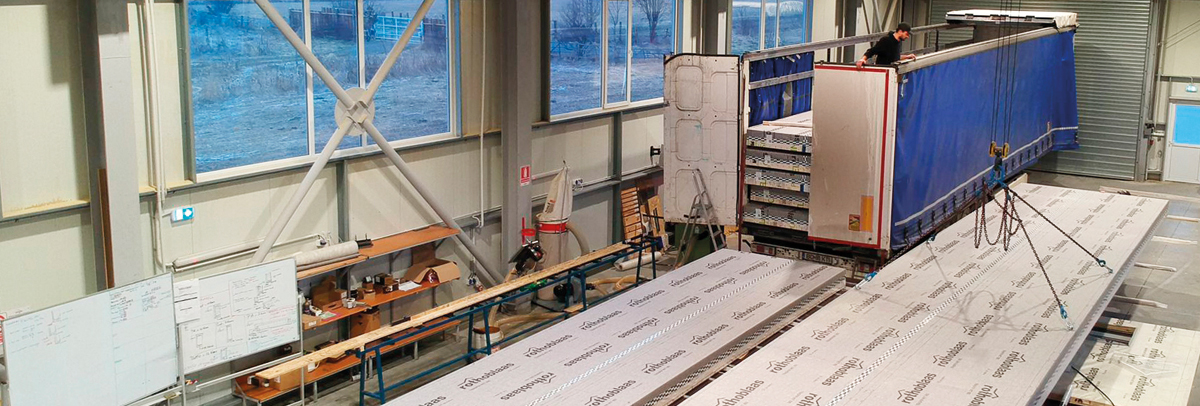

Application in a manufacturing plant

Having a horizontal panel available within a manufacturing plant offers a range of advantages that the construction site does not have:

- The panels are clean and free of “construction site” dust

- Consequently, membrane adhesion will be better and stable

- “Horizontal” application is much faster than vertical application where the panel is already positioned to be part of the building structure

- The application space will be significantly clearer of obstructions than on the building site

- The panel is delivered ready to use and protected from weathering

- Operators doing the pre-fitting have greater comfort

- They are protected from dust, rain and wind

Why a self-adhesive product

In addition to speeding up the application and adhesion of the membrane to the panel, the high-performance adhesive will avoid the typical problems of transportation to the construction site.

Pre-fitted non-self-adhesive products do not guarantee the same performance as products that are so. Consider a non-adhesive membrane that is fitted to a CLT panel before it arrives at the construction site: mechanical fastening with staples is not as fast as adhesive fastening and will result in numerous micro-slits that must be repaired with sealant tape.

A mechanically fastened membrane may have problems detaching from the staple due to air friction both during transport and while on the construction site.

A further competitive advantage of adhesive products is that they maintain a certain degree of waterproofing despite accidental tears or in cases where it is necessary to puncture them.

Let’s consider a membrane pre-fitted on a CLT panel. To transport the building element to the construction site, it is necessary to insert lifting hooks and then drill at least two holes.

For a self-adhesive membrane, infiltrations of water or moisture will not affect the performance of the CLT because the problem will remain confined to the perforated surface. In contrast, the risk of damage for a panel with a non-adhesive membrane is higher.

The steps of installing a Rothoblaas self-adhesive membrane

Unrolling, gluing edges toward the centre, adhering by roller pressure. Their ease of application gives a huge advantage to these types of products already designed to be high-performing.

Rothoblaas’ main self-adhesive membranes are: TRASPIR ADHESIVE 260, BARRIER NET ADHESIVE 200, VAPOR ADHESIVE 260. Using high-performance adhesives, they are all suitable for application to rough surfaces while maintaining the functions for which they were designed.

Specifically, BARRIER NET ADHESIVE vapour barrier features a reinforcing grid that provides very high mechanical strength and reduces the risk of slipping. Since it is transparent, it is especially ideal for protecting buildings with exposed timber façades.

Learn more

Rothoblaas membranes consist of several layers. They are always comprised of a functional film that ensures perfect waterproofing and airtightness and one or more reinforcing layers that provide protection for the functional film. This structured composition increases the mechanical performance and abrasion resistance of all our membranes. With the aim of supporting modular and prefabricated construction, Rothoblaas is expanding its range of membranes, sealants and self-adhesive tapes.

CLICK HERE for further information and contexts of use for Rothoblaas’ self-adhesive membranes

Leave a Reply

Want to join the discussion?Feel free to contribute!