Groundbreaking British invention could help industry slash bills by 45 percent and radically cut CO2

- New type of heat battery allows users to swap expensive gas and electricity for cheap on-site solar instead.

- Bills cut by over 45% with an annual saving of £915,000.

- Payback in as little as 6 years.

- 1,000 tonnes of CO2 avoided per year.

- Inventors Caldera already have £4.3 million backing from UK Government.

- Potential ‘major positive impact’ on UK net zero ambitions.

A groundbreaking British invention could help industry slash energy bills by 45 percent and radically reduce CO2.

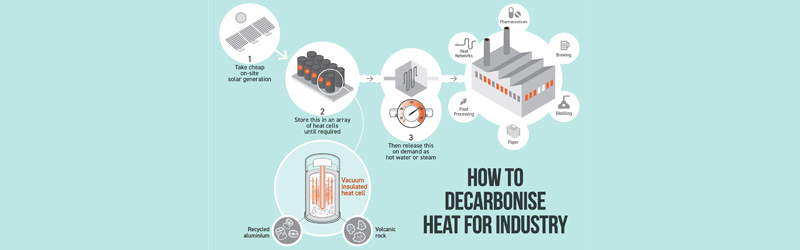

Hampshire startup Caldera has developed a unique type of heat storage system, which takes cheap on-site solar power and stores it as heat in specially designed cells made of scrap aluminium and volcanic rock.

These cells then deliver heat when required as hot water or steam, the main energy source for many processes in pharmaceuticals, food manufacturing and brewing.

This allows businesses to switch off high-cost gas and electricity and use cheap on-site solar instead.

Now independent analysis by energy consultants Gemserv shows this system could slash fuel bills by 45 percent, saving a typical business hundreds of thousands of pounds a year.

The calculations are based on a real-life British food factory using its own on-site solar array, where Gemserv predicted an annual energy saving of £915,000 and a reduction of more than 1,000 tonnes of CO2 emitted per year. Installation of the system could pay for itself in less than six years, the analysis states.

In June, Caldera was awarded £4.3 million from the UK Department for Energy Security & Net Zero to build a full-scale demonstrator at their Southampton site, where they will showcase the technology.

They are currently crowd raising on Crowdcube and have already surpassed 150 percent of their target raise.

“Energy bills are a major headache for industry, and in particular the high and volatile price of gas,” explains company co-founder and CEO James Macnaghten.

“In contrast, solar power is getting cheaper by the month. Our technology allows factory owners to use low-cost solar electricity which can be stored in super-insulated cells to be used when required,” James says.

Caldera has targeted their technology at factories which use industrial steam – which accounts for 31 percent of all UK industrial energy use.

“Many businesses have not yet realised the huge potential for installing a dedicated solar farm – even where little roof space is available,” James continues.

“It’s often possible to lease land for a solar farm in the vicinity and run a dedicated cable – known as a ‘private wire’ – for a kilometre or more to the industrial site. In our case study, the food factory plans a 7MW solar array on land nearby.

“Our system completely bypasses the need to connect to the grid, which can take years, and means the factory owner can generate and use all of their solar energy at cost.

“This transforms the economics of solar power and gives the site owner price certainty over decades, allowing manufacturers to focus on their core business, and not on the price of gas.

“This Gemserv report backs up our own internal findings. We believe the widespread adoption of Caldera’s industrial heat storage system would bring significant benefits to many British manufacturers and could have a major positive impact our net zero ambitions,” James concludes.

Inside a heat cell

Each heat cell houses a solid core of aluminium-rock composite encased in vacuum insulation which can store heat at temperatures from 200 to 500C.

These modular cells can store this with very high efficiency for hours, ready to deliver heat on demand at temperatures between 80 to 200 C – the sweet spot for many industrial processes.

This allows industrial users to capitalise on super-cheap solar energy, which can be generated on-site (or on land nearby) and stored ready for use when required.

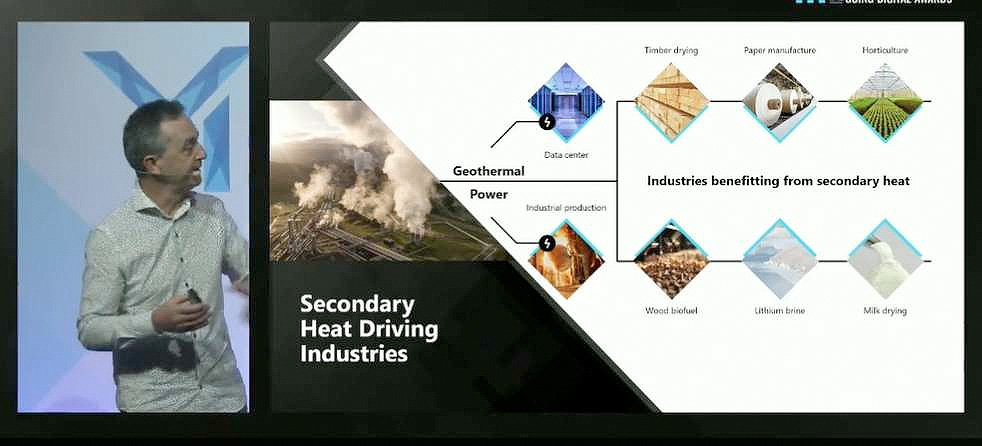

For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.

For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.

The alternative is whole site flow reduction. Fitting a device such as Groundbreaker’s NRv2 LoFlo, at the meter regulates the level of flow entering customer premises – regardless of network pressure. As the flow of water into the premises is limited, then the amount used in ‘time controlled’ activities is also limited – but without providing a degradation of service. More importantly not requiring any intervention or behavioural change on the part of the customer, so leading to ‘natural’ reduction in consumption. Our water companies are regulated to provide a minimum level of water supply, but in many areas, due to network structure and gravity fed systems, supply is much greater. Households in high pressure areas could be receiving up to three times the required minimum levels. So, run a hose for five minutes at the bottom of the hill, and your lawn will be greener that the gardener that does the same at the top. ‘Time controlled’ uses could be reduced if all households received the same acceptable, ‘standardised’ supply. Independent research carried out by WRc, showed a theoretical reduction of 2-4% of typical water usage when devices such as LoFlo are installed. However, recent field trials by a major UK water company have showing savings of 5%. As part of UK Net Zero Carbon targets water companies have been targeted to reduce the water householders are using, Per Capita Consumption (PCC). PCC reduction targets average just under 6% in the UK, so utilising property flow restriction could achieve just 1% off the average PPC reduction targets! However, water companies are also tied to customer performance commitment levels (C-Mex), and some seem to be concerned that a reduction in the supply levels to properties will prompt customer complaints, offsetting the financial rewards of achieving PCC targets. Field trials of devices such as LoFlo, have shown that most customers are not aware of supply levels in their property, within certain limits. Especially when moving into a new property, customers accept the levels as ‘being what it is’ and fears of an increase in customer complaints impacting C-Mex values are overrated. In recent trials in England, where occupants did notice the change in supply, it was the positive impact of reduced flow that was cited, e.g. reduced splashing at the kitchen sink. Not a single occupant wanted the LoFLo to be removed after the trial period

The alternative is whole site flow reduction. Fitting a device such as Groundbreaker’s NRv2 LoFlo, at the meter regulates the level of flow entering customer premises – regardless of network pressure. As the flow of water into the premises is limited, then the amount used in ‘time controlled’ activities is also limited – but without providing a degradation of service. More importantly not requiring any intervention or behavioural change on the part of the customer, so leading to ‘natural’ reduction in consumption. Our water companies are regulated to provide a minimum level of water supply, but in many areas, due to network structure and gravity fed systems, supply is much greater. Households in high pressure areas could be receiving up to three times the required minimum levels. So, run a hose for five minutes at the bottom of the hill, and your lawn will be greener that the gardener that does the same at the top. ‘Time controlled’ uses could be reduced if all households received the same acceptable, ‘standardised’ supply. Independent research carried out by WRc, showed a theoretical reduction of 2-4% of typical water usage when devices such as LoFlo are installed. However, recent field trials by a major UK water company have showing savings of 5%. As part of UK Net Zero Carbon targets water companies have been targeted to reduce the water householders are using, Per Capita Consumption (PCC). PCC reduction targets average just under 6% in the UK, so utilising property flow restriction could achieve just 1% off the average PPC reduction targets! However, water companies are also tied to customer performance commitment levels (C-Mex), and some seem to be concerned that a reduction in the supply levels to properties will prompt customer complaints, offsetting the financial rewards of achieving PCC targets. Field trials of devices such as LoFlo, have shown that most customers are not aware of supply levels in their property, within certain limits. Especially when moving into a new property, customers accept the levels as ‘being what it is’ and fears of an increase in customer complaints impacting C-Mex values are overrated. In recent trials in England, where occupants did notice the change in supply, it was the positive impact of reduced flow that was cited, e.g. reduced splashing at the kitchen sink. Not a single occupant wanted the LoFLo to be removed after the trial period