For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.

For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.

Grant, a presenter and panellist at the Bentley Year in Infrastructure and Going Digital Awards hosted in Singapore, spoke both on the critical minerals crisis, as well as the massive untapped role geothermal energy can play in industry, likening the Earth and its heat to “the world’s largest power station.”

Directing audience members to look down at their shoes, Grant illustrated how what was actually being looked at was this theoretical and literal power station: “The centre of the Earth is the same heat as the sun. It’s 6,500km (down), which means that the Earth is a huge, big battery. It’s a massive power station to be exploited.”

This innate heat, energy generated from underground, is geothermal energy, which Grant explained is “interesting in that it’s a base load source of power and any reliable grid in the world needs baseload power.

“Not only is it baseload, it’s also surge power – you can take a geothermal power station, turn it up, turn it down and use it to baseload capacity manage a power network.”

Low heat exhaust pipes

Geothermal energy is high temperature and generates electricity, but Grant added that another facet of geothermal comes from the potential of resulting low temperature heat from geothermal power plants.

Likening it to the example of a car’s exhaust pipe, Grant said: “If you think about the exhaust pipe on your car what comes out the back of the plant is low temperature heat which can be used for heating, as opposed to electricity production.”

To demonstrate, he cited the use case of Paris, France, which has seen approximately 2 million people heat their households from water sourced from below the ground.

“For the last 30 years, they’ve been tapping aquifers 2,000 meters down and pulling 60°C water to the surface and heating the city.

“Just on the other side of Singapore Island, at Sembawang, they’ve been drilling 1,000 meters down and NTU (Nanyang Technological University) has been running a research project to pull hot water from underneath Singapore and use it for cooling.”

However, added grant, the value case for geothermal goes beyond the surface value of household heating – it provides the foundation upon which industry can built.

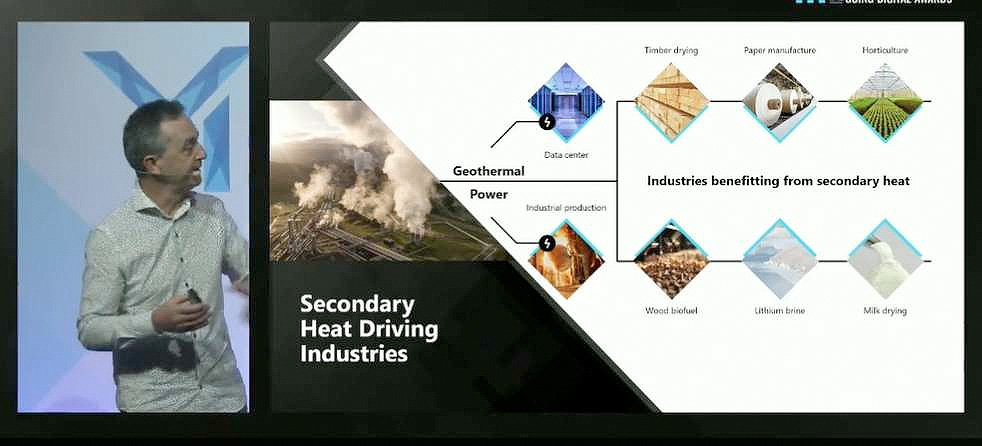

“Geothermal is more than electricity and it’s more than heat, because around that heat you can build an industrial ecosystem.

“If we take New Zealand as an example – where the base load power is used for Microsoft’s new data centre, which is 100% renewable energy, it’s used for steel-making – that exhaust heat is used for a whole bunch of things.

“It’s used for milk drying, which is New Zealand’s largest export industry. It’s used for vegetable production, for heating hot houses. We’re a pretty cold country in the Winter, but we can produce these amazing, high-quality vegetables all year round.

“In fact, Contact Energy, who is a Founders Award winner this year at the Bentley Going Digital show, supports timber drying, the development of biofuels, but they are also developing the first industrial park that’s been commissioned by First Nations people in New Zealand to encourage the development of businesses that will use low-cost secondary heat that comes off the back of the geothermal power plant.

“So that creates a whole industrial and community ecosystem around that heat.”

Understanding the underground

According to Grant, to best optimise the use of geothermal energy for industry, understanding its nature will be of key importance.

“To do all of this, you need extremely powerful technology to understand the underground and you need to unlock this concept of digital insight that helps drive this level of sophistication.”

Grant related this to the work of Seequent, which creates and integrates earth modelling and geo-data management software.

“Understanding the underground was a concept related not only to geothermal but across energy sources.”

Supply side interlock

Specifically, Grant referenced the idea of a “supply and demand” interlock that both industry and politics have been battling.

“New forms of energy are heavily metal-consumptive and our challenge is where we are going to find the resources we need for the energy transition.”

Citing the mineral consumption by clean tech such as lithium-ion batteries, which are forecast to increase five times over in the next nine years, and offshore wind turbines, Grant stated that, as we continue to use this tech, demand for its metal has been continuing to exponentially increase.

Citing data from the International Energy Agency, he compared the mineral demand stemming from offshore renewable energy and gas-fired power generation.

Although renewables are clearly the way to go, he states, when generating the same amount of power, the latter uses nearly 13 times less the amount of minerals.

“We’re generating this supply and demand interlock and a timing problem where, for example, the factory that makes those batteries can now be constructed in under a year but the mine to supply them will now take between 15 and 20 years to build.

“Governments are waking up to supply side problem, to the demand side shift that we’re creating, and now the issue of critical minerals supply is on the national agenda of almost every government in the world.”

Source: Power Engineering International

For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.

For Graham Grant, CEO of Bentley-owned software company Seequent, geothermal energy, beyond its application for heating, provides the perfect setting upon which industry, from vegetable farming to steel making, can thrive.

environment.

environment.

Deceuninck has invested more the €15million in one of the world’s most advanced PVC-U recycling and compounding facilities.

Deceuninck has invested more the €15million in one of the world’s most advanced PVC-U recycling and compounding facilities.