Simpson Strong-Tie are all set to provide the steel frame construction industry with performance tested connectors and fixings with the release of our brand new 2021 Connectors for Light Gauge Steel catalogue.

Created for suppliers, architects, engineers, erectors, and contractors alike, the new catalogue makes it easy to specify project-appropriate LGS connector solutions, with robust product pages including detailed features and benefits, technical data and installation advice, as well as associated fasteners and tools.

Light gauge steel (LGS) enables quick construction without the need for heavy tools or equipment. LGS systems offer a range of construction related benefits, with speed of construction, cost effectiveness and safety being the most notable.

Whether you are a manufacturer of LGS load-bearing structures or a manufacturer of light gauge steel facades, Simpson Strong-Tie can provide a suitable connection solution. From steel joist connectors to oversail movement connectors, bridge connectors and ties, to chemical and mechanical anchor systems, our comprehensive range of products will ensure you make the right connection, when you need it.

The new catalogue features the ever popular TJC Jack Truss and Rafter Connector, an on-site adjustable angle bracket for connecting angled LGS sections, and the HTT5 Tension Ties, as well as the heavy-duty Quik Drive collated fastening system. Also showcased are some brand new product innovations, including:

• The LGSSC Splicing Clip, designed to connect the over–sail LGS studs to the primary structure in continuous walling installations.

• The RCKW Parapet Wall Bracket, designed to resist an over-turning moment at the base of exterior knee-walls and parapets as well as interior partial height walls.

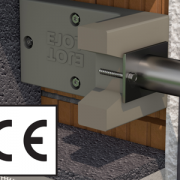

• X1214 screws have a #3 drill point capable of drilling through 5mm steel and suitable for 450 grade hardened steel.

• X1224 screws have #5 drill point capable of drilling through 12.5mm steel and suitable for fixing to hot rolled steel sections.

“Our range of ergonomically designed connectors can assist on-site installation and ensure projects are completed on time and to your specification. Whether you need products or design, solving your structural problems is our passion, and the 2021 LGS connectors catalogue makes it easy to find information and project solutions quickly.” Explains Sales Manager @MartinKeithLister.

“You also have the reassurance of knowing that you are specifying a tested product, whether it be a hold down, anchored to the foundation, or an adjustable angle bracket connecting to the light gauge steel, our dedicated technical support team are available daily to help you select your connector and the fixing solution.”

As the market grows for steel framing solutions and buildings built in an offsite environment, our research continues at head office into our upcoming range of Ready products that will revolutionise the future of light gauge steel.

To learn more about how Simpson Strong-Tie can help you develop your light gauge steel project call us on 01827 255 600.

The new catalogue is available now, or you can download the catalogue from the Literature Library on the website.