Reassesing design and project delivery

#constructionindustry #sustainable #architects #localauthorities #contractors #developers #innovation #buildingtechnology #mmc #newnormal #drainage @PolypipeHome

By Adam Cafer, Polypipe Building Services.

So far 2020 is turning into a transformative year for the construction sector, in ways that no industry analyst could have predicted. There had been a concerted push from industry bodies and the boardrooms of major construction companies to ensure changes in practices were undertaken, driven by the recommendations of the Hackett Review, and in preparation for Brexit.

However the COVID-19 pandemic, which will be the defining event for 2020 and the coming years, is creating the need for construction companies, manufacturers and contractors to reassess how they design and deliver projects. With the Nightingale hospitals the shining example of how embracing digital solutions, offsite construction and increased collaboration can deliver projects efficiently in a short space of time, the construction industry has shown its ability to adapt and the opportunity more widespread adoption of these processes present.

Up until now, there have been pockets of innovation in the construction sector as companies have looked to modernise and implement digital and smart construction methods as well as explore offsite modular construction. Progress felt incremental and like it could take a generation to implement. However, as companies have had to adapt during the pandemic, necessity became the mother of invention and there has been a dramatic increase in innovation, not only onsite but throughout the supply chain.

The first challenge the construction industry had to overcome, after making the decision whether to close sites or remain open, was the implementation of social distancing and more specifically the guidelines introduced by the Construction Leadership Council.

To support construction sites returning to work, elements within the supply chain needed to focus on service as well as the products delivered. Contractors should challenge suppliers to see how they can help reduce risk to their people and suppliers should think about how they can help contractors maintain social distancing without losing productivity.

Innovating through offsite, by removing as much of the install preparation done onsite as possible, will be one way the supply chain can offer support.

To create valuable space to assist with proximity measures, sites will need to reduce areas taken up with container loads of product and turn to the supply chain to deliver just in time.

Delivery times may also be restricted as work is planned with staggered starts and finishes with access procedures changing, making it important for delivery companies adapt to changes to ensure quick and easy deliveries managed by fewer people.

Furthermore, contractors will be looking to innovate where possible to allow activities to be completed by as few people as possible. Suppliers could help by reviewing installation of materials and use offsite solutions to minimise the number of people having to install on site.

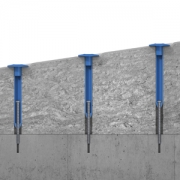

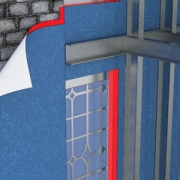

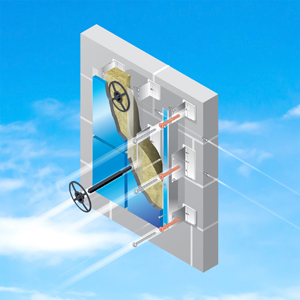

Polypipe Building Services is supporting contractors returning to site through its fabrication service. Polypipe Advantage delivers offsite fabricated Terrain drainage stacks and MecFlow water supply kits just in time, floor by floor. Stillages of the lightweight material can be craned to each level and installation can be carried out by one person.

Specialist on-site teams are given access to dedicated Polypipe Advantage project managers, who co-ordinate an exact delivery schedule for the project. This means that the manufactured drainage stacks only reach site when they are required, ensuring they can be installed straight away, with no need for additional on-site storage. This provides a way to maintain project progress under stricter site safety and COVID-safe restrictions.

Every fabricated drainage stack from trusted Polypipe brand, Terrain, is manufactured under factory controlled conditions, then delivered and assembled based on the exact specifications of the project. This provides added assurance that the final system delivered will be precise for the end-purpose of the completed project.

At a moment of great complexity for the industry, the Polypipe Advantage service helps to keep it simple, and offers an established solution and system to support contractors get back to work and keep their projects on time and on track. Moving into the future, services such as Polypipe Advantage, that embrace the trends of digital transformation, and better managed use of resources will provide the foundation for the changing face of construction and the way we build infrastructure, tall buildings and new homes.

www.polypipe.com

variety of scope from the projects shows Totally Modulars commitment to the whole MMC journey, as the projects show a combination of accelerated housing delivery, digital planning and production technologies that will enable the industry to attain new levels of quality, variability, and efficiency.

variety of scope from the projects shows Totally Modulars commitment to the whole MMC journey, as the projects show a combination of accelerated housing delivery, digital planning and production technologies that will enable the industry to attain new levels of quality, variability, and efficiency.