Cooling the planet by filtering excess carbon dioxide out of the air on an industrial scale would require a new, massive global industry – what would it need to work?

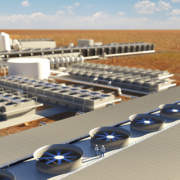

The year is 2050. Walk out of the Permian Basin Petroleum Museum in Midland, Texas, and drive north across the sun-baked scrub where a few remaining oil pumpjacks nod lazily in the heat, and then you’ll see it: a glittering palace rising out of the pancake-flat ground. The land here is mirrored: the choppy silver-blue waves of an immense solar array stretch out in all directions. In the distance, they lap at a colossal grey wall five storeys high and almost a kilometre long. Behind the wall, you glimpse the snaking pipes and gantries of a chemical plant.

As you get closer you see the wall is moving, shimmering – it is entirely made up of huge fans whirring in steel boxes. You think to yourself that it looks like a gigantic air conditioning unit, blown up to incredible proportions. In a sense, that’s exactly what this is. You’re looking at a direct air capture (DAC) plant, one of tens of thousands like it across the globe. Together, they’re trying to cool the planet by sucking carbon dioxide out of the air. This Texan landscape was made famous for the billions of barrels of oil pulled out of its depths during the 20th Century. Now the legacy of those fossil fuels – the CO2 in our air – is being pumped back into the emptied reservoirs.

If the world is to meet Paris Agreement goals of limiting global warming to 1.5C by 2100, sights like this may be necessary by mid-century.

We have a climate change problem and it’s caused by an excess of CO2. With direct air capture, you can remove any emission, anywhere, from any moment in time – Steve Oldham

But step back for a moment to 2021, to Squamish, British Columbia where, against a bucolic skyline of snowy mountains, the finishing touches are being put to a barn-sized device covered in blue tarpaulin. When it becomes operational in September, Carbon Engineering’s prototype direct air capture plant will begin scrubbing a tonne of CO2 from the air every year. It is a small start, and a somewhat larger plant in Texas is in the works, but this is the typical scale of a DAC plant today.

“We have a climate change problem and it’s caused by an excess of CO2,” says Carbon Engineering chief executive Steve Oldham. “With DAC, you can remove any emission, anywhere, from any moment in time. It’s very powerful tool to have.”

Most carbon capture focuses on cleaning emissions at the source: scrubbers and filters on smokestacks that prevent harmful gases reaching the atmosphere. But this is impractical for small, numerous point sources like the planet’s billion or so automobiles. Nor can it address the CO2 that is already in the air. That’s where direct air capture comes in.

The number of things that would have to happen without direct air capture are so stretching and multiple it’s highly unlikely we can meet the Paris Agreements without it – Ajay Gambhir

If the world wants to avoid catastrophic climate change, switching to a carbon neutral society is not enough. The Intergovernmental Panel on Climate Change (IPCC) has warned that limiting global warming to 1.5C by 2100 will require technologies such as DAC for “large-scale deployment of carbon dioxide removal measures” – large-scale meaning many billions of tonnes, or gigatonnes, each year. Elon Musk recently pledged $100m (£72m) to develop carbon capture technologies, while companies such as Microsoft, United Airlines and ExxonMobil are making billion-dollar investments in the field.

“Current models suggest we’re going to need to remove 10 gigatonnes of CO2 per year by 2050, and by the end of the century that number needs to double to 20 gigatonnes per year,” says Jane Zelikova, a climate scientist at the University of Wyoming. Right now, “we’re removing virtually none. We’re having to scale from zero.”

Carbon Engineering’s plant in Squamish is designed as a testbed for different technologies. But the firm is drawing up blueprints for a much larger plant in the oil fields of west Texas, which would fix 1 million tonnes of CO2 annually. “Once one is done, it’s a cookie cutter model, you simply build replicas of that plant,” says Oldham. Yet he admits the scale of the task ahead is dizzying. “We need to pull 800 gigatonnes out of the atmosphere. It’s not going to happen overnight.”

Blue-sky thinking

The science of direct air capture is straightforward. There are several ways to do it, but the one that Carbon Engineering’s system uses fans to draw air containing 0.04% CO2 (today’s atmospheric levels) across a filter drenched in potassium hydroxide solution – a caustic chemical commonly known as potash, used in soapmaking and various other applications. The potash absorbs CO2 from the air, after which the liquid is piped to a second chamber and mixed with calcium hydroxide (builder’s lime). The lime seizes hold of the dissolved CO2, producing small flakes of limestone. These limestone flakes are sieved off and heated in a third chamber, called a calciner, until they decompose, giving off pure CO2, which is captured and stored. At each stage, the leftover chemical residues are recycled back in the process, forming a closed reaction that repeats endlessly with no waste materials.

We’re past the point where reducing emissions needed to take place. We’re locking in our reliance on DAC more and more – Jane Zelikova

With global carbon emissions continuing to rise, the climate target of 1.5C is looking less and less likely without interventions like this.

“The number of things that would have to happen without direct air capture are so stretching and multiple it’s highly unlikely we can meet the Paris Agreements without it,” says Ajay Gambhir, senior researcher at the Imperial College Grantham Institute for Climate Change and an author of a 2019 paper on the role of DAC in climate mitigation.

The IPCC does present some climate-stabilising models that don’t rely on direct air capture, but Gambhir says these are “extremely ambitious” in their assumptions about advances in energy efficiency and people’s willingness to change their behaviour.

“We’re past the point where reducing emissions needed to take place,” says Zelikova. “We’re locking in our reliance on DAC more and more.”

DAC is far from the only way carbon can be taken out of the atmosphere. Carbon can be removed naturally through land use changes such as restoring peatland, or most popularly, planting forests. But this is slow and would require huge tracts of valuable land – foresting an area the size of the United States, by some estimates, and driving up food prices five-fold in the process. And in the case of trees, the carbon removal effect is limited, as they will eventually die and release their stored carbon, unless they can be felled and burned in a closed system.

The scale of the challenge for carbon removal using technologies like DAC, rather than plants, is no less gargantuan.  Gambhir’s paper calculates that simply keeping pace with global CO2 emissions – currently 36 gigatonnes per year – would mean building in the region of 30,000 large-scale DAC plants, more than three for every coal-fired power station operating in the world today. Each plant would cost up to $500m (£362m) to build – coming in at a cost of up to $15 trillion (£11tn).

Gambhir’s paper calculates that simply keeping pace with global CO2 emissions – currently 36 gigatonnes per year – would mean building in the region of 30,000 large-scale DAC plants, more than three for every coal-fired power station operating in the world today. Each plant would cost up to $500m (£362m) to build – coming in at a cost of up to $15 trillion (£11tn).

Every one of those facilities would need to be stocked with solvent to absorb CO2. Supplying a fleet of DAC plants big enough to capture 10 gigatonnes of CO2 every year will require around four million tonnes of potassium hydroxide, the entire annual global supply of this chemical one and a half times over.

Carbon Engineering’s pilot plant in British Columbia, is the “cookie cutter” model

for much larger DAC plants (Credit: Carbon Engineering)

And once those thousands of DAC plants are built, they also need power to run. “If this was a global industry absorbing 10 gigatonnes of CO2 a year, you would be expending 100 exajoules, about a sixth of total global energy,” says Gambhir. Most of this energy is needed to heat the calciner to around 800C – too intense for electrical power alone, so each DAC plant would need a gas furnace, and a ready supply of gas.

Costing the planet

Estimates of how much it costs to capture a tonne of CO2 from the air vary widely, ranging from $100 to $1,000 (£72 to £720) per tonne. Oldham says that most figures are unduly pessimistic – he is confident that Climate Engineering can fix a tonne of carbon for as little as $94 (£68), especially once it becomes a widespread industrial process.

A bigger issue is figuring out where to send the bill. Incredibly, saving the world turns out to be a pretty hard sell, commercially speaking. Direct air capture does result in one valuable commodity, though: thousands of tonnes of compressed CO2. This can be combined with hydrogen to make synthetic, carbon-neutral fuel. That could then be sold or burned in the gas furnaces of the calciner (where the emissions would be captured and the cycle continue once again).

Surprisingly, one of the biggest customers for compressed CO2 is the fossil fuel industry.

As wells run dry, it’s not uncommon to squeeze the remaining oil out of the ground by pressuring the reservoir using steam or gas in a process called enhanced oil recovery. Carbon dioxide is a popular choice for this, and comes with additional benefit of locking that carbon underground, completing the final stage of carbon capture and storage. Occidental Petroleum, which has partnered with Carbon Engineering to build a full-scale DAC plant in Texas, uses 50 million tonnes of CO2 every year in enhanced oil recovery. Each tonne of CO2 used in this way is worth about $225 (£163) in tax credits alone.

It’s perhaps fitting that the CO2 in our air is eventually being returned underground to the oil fields from whence it came, although maybe ironic that the only way to finance this is in the pursuit of yet more oil. Occidental and others hope that by pumping CO2 into the ground, they can drastically reduce the carbon impact of that oil: a typical enhanced-recovery operation sequesters one tonne of CO2 for every 1.5 tonnes it ultimately releases in fresh oil. So while the process reduces the emissions associated with oil, it doesn’t balance the books.

Though there are other uses that may become more commercially viable. Another direct air capture company, Climeworks, has 14 smaller scale units in operation sequestering 900 tonnes of CO2 a year, which it sells to a greenhouse to enhance the growth of pickles. It’s now working on a longer-term solution: a plant under construction in Iceland will mix captured CO2 with water and pump it 500-600m (1,600-2,000ft) underground, where the gas will react with the surrounding basalt and turn to stone. To finance this, it offers businesses and citizens the ability to buy carbon offsets, starting at a mere €7 (£6) per month. Can the rest of the world be convinced to buy in?

“DAC is always going to cost money, and unless you’re paid to do it, there is no financial incentive,” says Chris Goodall, author of What We Need To Do Now: For A Zero Carbon Future. “Climeworks can sell credits to virtuous people, write contracts with Microsoft and Stripe to take a few hundred tonnes a year out of the atmosphere, but this needs to be scaled up a millionfold, and that requires someone to pay for it.

“There are subsidies for electric cars, cheap financing for solar plants, but you don’t see these for DAC,” says Oldham. “There is so much focus on emission reduction, but there isn’t the same degree of focus on the rest of the problem, the volume of CO2 in the atmosphere. The big impediment for DAC is that thinking isn’t in policy.”

Zelikova believes that DAC will follow a similar path to other climate technologies, and become more affordable. “We have well-developed cost curves showing how technology can go down in cost really quickly,” says Zelikova. “We surmounted similar hurdles with wind and solar. The biggest thing is to deploy them as much as possible. It’s important for government to support commercialisation – it has a role as a first customer, and a customer with very deep pockets.”

Goodall advocates for a global carbon tax, which would make it expensive to emit carbon unless offsets were purchased. But he recognises this is still a politically unpalatable option. Nobody wants to pay higher taxes, especially if the externalities of our high-energy lifestyles – increasing wildfires, droughts, floods, sea level rise – are seen as being shouldered by somebody else.

Zelikova adds we also need broader conversation in society about how much these efforts should cost. “There is an enormous cost in climate change, in induced or exacerbated natural disasters. We need to do away with idea that DAC should be cheap.”

Risk and reward

Even if we agree to build 30,000 industrial scale DAC plants, find the chemical materials to run them, and the money to pay for it all, we won’t be out of the woods yet. In fact, we might end up in a worse position than before, thanks to a phenomenon known as mitigation deterrence.

“If you think DAC is going to be there in the medium- to long-term, you will not do as much near-term emissions reduction,” explains Gambhir. “If the scale-up goes wrong – if it turns out to be difficult to produce the sorbent, or that it degrades more quickly, if it’s trickier technologically, if turns out to be more expensive than expected, then in a sense by not acting quickly in the near-term, you’ve effectively locked yourself into a higher temperature pathway.”

Critics of DAC point out that much of its appeal lies in the promise of a hypothetical technology that allows us to continue living our carbon-rich lifestyles. Yet Oldham argues that for some hard-to-decarbonise industries, such as aviation, offsets that fund DAC might be the most viable option. “If it’s cheaper and easier to pull carbon out of air than to stop going up in the air, maybe that is what DAC plays in emission control.”

Gambhir argues that it’s not an “either-or” situation. “We need to rapidly reduce emissions in the near-term, but at same time, determinedly develop DAC to work out for sure if it’s going to be there for us in the future.” Zelikova agrees: “It’s a ‘yes, and’ situation,” she says. “DAC is a critical tool to balance out the carbon budget, so what we can’t eliminate today can be removed later.”

As Oldham seeks to scale up Carbon Engineering, the biggest fundamental factor is proving large scale DAC is “feasible, affordable and available”. If he’s successful, the future of our planet’s climate may once again be decided in the oil fields of Texas.

Source: Future Planet (BBC)

Gambhir’s paper calculates that simply keeping pace with global CO2 emissions – currently 36 gigatonnes per year – would mean building in the region of 30,000 large-scale DAC plants, more than three for every coal-fired power station operating in the world today. Each plant would cost up to $500m (£362m) to build – coming in at a cost of up to $15 trillion (£11tn).

Gambhir’s paper calculates that simply keeping pace with global CO2 emissions – currently 36 gigatonnes per year – would mean building in the region of 30,000 large-scale DAC plants, more than three for every coal-fired power station operating in the world today. Each plant would cost up to $500m (£362m) to build – coming in at a cost of up to $15 trillion (£11tn).