Rick Murcock founder and CEO of US company Autovol thinks it will be.

An affordable apartment building for one of the nation’s most expensive markets is being built right now in Idaho.

The five-story building, with 301 apartments for seniors, isn’t for Boise. Instead, Virginia Street Studios will open in San Jose, the sixth-most expensive city in the United States, where median home prices hover around $1.4 million.

A Nampa company, Autovol Volumetric Modular, is creating the building module by module inside a 400,000-square-foot factory on Star Road that cost $100 million to build. As they’re completed, the 160 modules are loaded onto semi trucks and driven by Boise-based Western Home Transport to the Bay Area for assembly.

So far, 133 modules have been completed, with the rest to be finished next week.

“Building it here and and shipping it into California saved a lot of money and works to lower the costs for affordable housing,” Autovol founder and CEO Rick Murdock said in an interview. “We produce multifamily, multi-story affordable housing with the idea that we want to save you 20% of your costs and 40% of your time.”

Longtime Treasure Valley residents bemoan the meteoric rise in local house and apartment-rental prices, even as homeowners and landlords quietly delight in the money rolling in. But the shortage of affordable housing is a nationwide problem, said Murdock, a longtime Idaho resident with 43 years of experience creating modular products.

He was co-founder of Guerdon Modular Buildings, a Boise modular building manufacturer, and Prefab Logic, which provides consultation services for clients using modular construction.

“California alone needs 11 million units,” Murdock said in an interview. “It’s an excellent market, and they’ve got probably the highest need in the western United States, and their cost structure is extremely high.”

It’s more efficient to build inside a factory, where changes in weather don’t hamper production, he said. The savings in time comes from being able to prepare a work site at the same time construction is taking place. In a site-built project, all of the prep work must be completed before construction can begin.

“Obviously, our labor rates are less than what they are in California,” Murdock said. “We’ll build it here, ship it and save the project about $100 a square foot.”

The cost savings aren’t enough to make Autovol’s buildings attractive to the Idaho market, he said.

Housing costs in Boise area keep rising

The median price for homes sold in Ada County in January set yet another a record $454,000, which was $19,100 above December’s mark, also a record, according to the Intermountain Multiple Listing Service. In the past five years, the median price in Idaho’s largest county has nearly doubled.

Meanwhile, the number of houses listed on the market continues to shrink. In January, there were 269 houses for sale, down from 333 in December.

In neighboring Canyon County, where prices have traditionally been much lower, January’s median of $338,490 was down $955 from December. It was the first time in a year that the Canyon County median did not set a record.

Autovol began work at its factory, located north of the Lactalis American Group cheese factory, about a year ago. It has 115 workers, with the workforce expected to increase to 250 by the end of 2021 and to 300 next year.

Robots are used to build walls, floors and ceilings and to assemble the modules. The machines are meant to relieve the “back-breaking work” of construction, Murdock said.

Autovol workers install wiring, plumbing and fixtures, and they perform inspections. They also create software programs that control the robots.

The robots have names, chosen by children of employees. Murdock’s executive assistant, Merrick Macomber, has a daughter who named one of the robots Stacy. Others include Sunflower and Lilly.

“We’ll have names on all of our robots and googly eyes so when they move around, you see them move,” Macomber said.

Autovol found labor force mostly from SW Idaho

Nearly all employees — what the company calls Solutioneers — are from the Treasure Valley, he said. They range from entry-level workers to people with master’s degrees in electrical and engineering, he said. Salaries range from $15 to $25 an hour, Murdock said.

Most of Autovol’s employees have worked for Murdock for more than 30 years at his other companies.

“Our team is made up of people with great character who are allowed to speak what’s on their mind and give fresh ideas,” he said. “We listen and take care of each other.”

The company is adding employees. There are listings for electricians, machine operators, floor, wall and ceiling fabricators, among others.

Autovol has several other affordable housing projects lined up in California, including a 186-unit project in American Canyon, south of Napa; a 193-unit building in Oakland; and a 160-unit building in Santa Maria, west of Bakersfield.

On-site assembly of the $10 million Virginia Street Studios building is scheduled to begin March 2 and should take about three weeks to complete, Murdock said. The modules cost about $126 per square foot to build. Cranes will lift the modules into place.

“It sounds funny, but it’s a lot like stacking Legos,” Murdock said.

Even as modular buildings have improved in quality since the days of single-wide trailers, Murdock said he still has to educate potential customers on how Autovol units rival the quality of site-built buildings. The Virginia Street Studios will prove that, he said.

“Once it’s ready, you would never think it was built in a factory,” Murdock said.

After the Virginia Street Studios building is completed — Autovol’s first project — he expects it will help recruit new clients by having a place to show them.

“The finished building will speak for itself,” Murdock said. “I think it’s a better-quality product because you’re building it in a controlled environment.”

Murdock declined to disclose revenues. He said he expects Autovol to turn a profit before the end of 2021.

Autovol isn’t the only Idaho connection to the San Jose apartment project. The Pacific Cos., an Eagle residential and charter school developer that is a partner in Autovol, is the developer.

Led by CEO Caleb Roope, The Pacific Cos. operates 110 workforce and mixed-income developments with 6,000 units in eight Western states, along with three dozen senior apartment complexes with more than 1,300 units.

The Pacific Cos. is also developing the American Valley, Oakland and Santa Maria projects that Autovol is building.

Roope, who is an investor in Autovol with Murdock and several other people, could not be reached for comment.

When Autovol’s factory is fully operational, it will be able to produce 2,000 modules a year. That will hardly put a dent in the nation’s need for affordable housing, he said.

Murdock hopes Autovol’s experience will spawn competitors to better meet the need. He doesn’t care that he’s putting in the blood and sweat to perfect the process and make it more efficient.

“If we took all this information and held it to ourselves and didn’t share it, what gain would there be?” he said. “We’re going to produce only so many units out of this plant and after that, is that it? I’m looking at our entire industry. I see it through a slightly different looking-glass.”

Source: Idaho Statesman

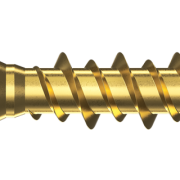

Floor fitters and home owners alike will be all too familiar with the curse of squeaky floorboards. Time after time the culprit is the fasteners; nails working loose over time, leading to expensive callbacks and customer dissatisfaction.

Floor fitters and home owners alike will be all too familiar with the curse of squeaky floorboards. Time after time the culprit is the fasteners; nails working loose over time, leading to expensive callbacks and customer dissatisfaction.