Ofwat’s Innovation Fund launches £4m open competition to reward innovators working in the construction industry with bold solutions for the water sector

- Ofwat today launches the Water Discovery Challenge, a new £4m competition for innovators outside of the water sector with bold ideas that can help solve some of its biggest challenges.

- Ofwat is calling on innovators working in the construction industry to apply their ingenuity and skills to deliver breakthrough solutions to be used by the water sector.

- Water companies provide drinking water and sewage services to over 50 million households in England and Wales, with a sewage network that could wrap around the world 13 times – yet the sector faces significant challenges due to increasing demand and climate change.

- The Water Discovery Challenge, the latest competition from Ofwat’s £200 million Innovation Fund, will fund innovation from sectors meeting similar challenges.

Today, England and Wales’ water regulator Ofwat launches the Water Discovery Challenge, a £4m competition for innovators working in the construction industry with bold and ingenious ideas that can solve the biggest challenges facing the water sector today and in the future.

The competition is the latest from Ofwat’s £200 million Innovation Fund, which seeks to generate new ideas to tackle issues including managing leaks, preventing pollution, improving water efficiency, reducing emissions, boosting flood and drought resilience, prioritising sustainable practices, and supporting vulnerable customers.

Where previous Ofwat Innovation Fund competitions have focused on innovations from, and led by, those within the sector, the new Water Discovery Challenge is incentivising ideas from, and led by, those outside of the water sector – including in construction.

It is seeking solutions from industries dealing with similar challenges to those faced by the water sector, or implementing solutions that could benefit water and wastewater services in England and Wales – with no requirement for entrants to partner with a water company. The goal is to open the sector to new ground-breaking insights and thinking that benefit consumers and the environment.

Up to 20 teams of the most promising innovators will be awarded up to £50,000 to develop their ideas, with expert support and mentoring from water companies. Up to 10 will go on to win up to £450,000 to turn ideas into pilots.

David Black, Chief Executive of Ofwat said: “It’s no secret that the water sector has faced challenges in the last year. As a regulator we’re constantly pushing the sector to overcome these. Water affects everyone, and it’s time we see what the water sector can learn from astronauts, farmers, data specialists, architects and planners. This is about preparing the water sector for the future, and I look forward to the ideas that come out of it.”

John Russell, Senior Director at Ofwat, said: “Our £200m Innovation Fund has already supported projects that detect and fix leaks, capture carbon emissions from water processing plants to convert them into fuel, and remove fertilisers from waterways to be re-used in our food system. Now, we’re broadening the opportunity to innovators in any industry that can make a difference to improving the water system for all of us.”

Ofwat is looking for bold and innovative entrants from outside the water sector. It has identified five sectors where it believes there is particularly high potential for innovative crossovers: construction, energy, cities and transport, agriculture and farming, and digital, data and internet of things.

To deliver the competition, Ofwat is working with innovation prize experts Challenge Works, alongside global engineering, sustainability and water sector experts Arup, and Isle Utilities. In addition to financial incentives, successful teams will benefit from expert mentoring and capacity-building support, including access to insights and mentoring from water companies and support for scaling solutions for the extensive water network in England and Wales.

Holly Jamieson, Director at Challenge Works, said: “Our experience of nurturing and rewarding innovators across multiple challenge prizes has shown us that it is often the least likely suspects that can provide the solution with the greatest impact. And with the support of Arup and Isle Utilities, we can work closely with innovators from outside the water sector to turn great ideas into real-world solutions.”

Previous examples of Ofwat Innovation Fund winners that showcase the value of cross-sector collaboration with the construction sector include:

- Enabling Water Smart Communities – Designing new housing and urban environments to absorb excess water like a sponge during heavy rain events and cope with sustained drought by recycling “greywater”.

- Designer Liner – Aiming to line older pipes from the inside to prevent leaks and increase the lifespan of mains pipes.

- Community-Centric Rainwater Management – Asking communities to test new water butts called Sustainable Drainage Systems (SuDS) that will help manage the flow of rainwater and reduce risk of flooding in paved urban areas.

The Water Discovery Challenge is open to entries from today at 1200 (GMT)

and closes on 5 April 2023.

To find out more about the competition and enter,

visit waterinnovation.challenges.org

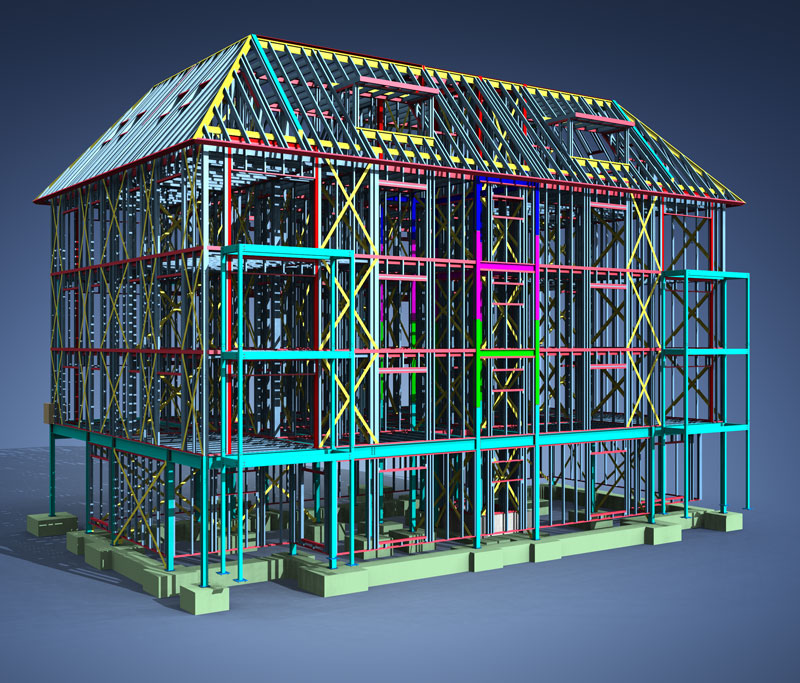

Vertex BD uses a high level of automation to rapidly reduce the time spent in the design phase, whilst giving its users the flexibility to build the way they need.

Vertex BD uses a high level of automation to rapidly reduce the time spent in the design phase, whilst giving its users the flexibility to build the way they need.

Already proving to be a true advocate for British businesses, rather than another apologist for foreign takeovers, the Business Secretary was also patriotically flying the flag for a home grown fusion power project, which promises to be the first commercially viable manifestation of the elusive Holy Grail of clean generation.

Already proving to be a true advocate for British businesses, rather than another apologist for foreign takeovers, the Business Secretary was also patriotically flying the flag for a home grown fusion power project, which promises to be the first commercially viable manifestation of the elusive Holy Grail of clean generation.