Why the octogenarian engineer Max Fordham claims ventilation is the worst excess of the building industry.

Max Fordham’s house is “simple and practical” and mostly all natural.

There has long been skepticism about Passive House, or Passivhaus in the original German. Passivhaus expert Monte Paulsen listed some of the misconceptions in a Green Building Advisor article a few years ago, including “too expensive” or “too stuffy” or “too complicated” or “too rigid” or “too ugly”. But in the years since it has become clear that none of these are true, and a lot of those skeptics have been won over.

According to Jason Walsh, writing in Passive House Plus, physicist and engineer Max Fordham used to be a bit of a skeptic and critic of the Passive House concept. But he independently developed his own approach to building energy efficient buildings, and it was looking more and more like Passive house. Fordham tells Passive House Plus that ventilation is the source of “the worst excesses of the building industry.” He then goes on about one of my regular gripes, radiant underfloor heating:

In particular, once you’ve solved the ventilation problem you’ve got a building that doesn’t really need any heating. What’s happening a lot with passive houses we’re seeing built is that people are demanding things like underfloor heating… I think it’s a conservatism: people are afraid, but it’s [passive house] then being adopted and people are adding underfloor heating to the brief. That’s the worst kind of heating to have, in a way, because if you have a thermally heavy [passive] building it doesn’t actually need any heating. So, if you don’t need any heating, you’d better not put in a heating system that is difficult to control and slow to control. It may look very luxurious and nice, but you can’t really turn it off. It’s just wasting heat.

Justin Bere, architect for the house, explains a bit of Max Fordham’s conversion:

Throughout his career he has, in his own way, developed his own version of passive house. He was on the same wavelength but didn’t know about it, and in this he brought together what he was doing and what the Passive House Institute was doing, saying: ‘Were both on the same mission to fight for the planet.’

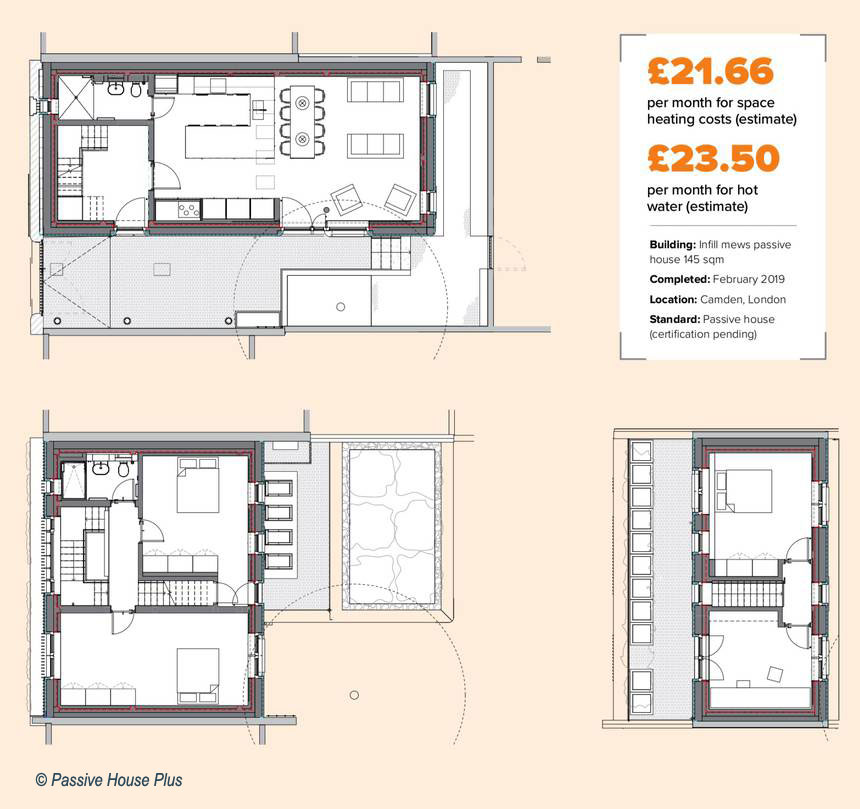

One very interesting thing about this house is that it is on three levels, and there doesn’t appear to be much of a concession to the fact that Max Fordham is in his eighties, other than the stairs do not have winders in them. Jason Walsh writes that “there is a focus on accessibility; it is possible to live entirely on the ground floor, for example, while cork flooring provides some safety against falls.” And the bathroom door on the ground floor opens outwards, but that is about it, and it is a tight ground floor suite.

But it is a very small mews site and Fordham almost seems to be treating this more as a physics experiment than a house. He tells Passive House Plus:

I’m just getting some feedback on the energy use. It’s very interesting: the top has the most glass and is getting the heat. It’s very cosy. The ground floor tends to need a little heat so I’ve just written a note that says that we need to increase the internal air flow. It’s very exciting getting some real feedback.

Readers should visit Passive House Plus for the technical details, but the house hits only .38 air changes per hour (PH limit is 0.6) and costs almost nothing to heat. It is built with natural and renewable materials including wood fibre insulation and wood cladding. There is a little electric heater coil in the Heat Recover Ventilator and a heat pump domestic hot water system.

One of the reasons that there used to be so many of the misconceptions about Passive House is that there really wasn’t a lot of experience with them. That has now changed. The builder, Bow Tie Construction, notes that some architects still don’t understand it.

Yesterday I spoke to an architect who said to me, ‘I don’t want to have to learn all this [in advance]. I want you to show me.’ One really interesting thing that comes to mind is that we try to specialise in passive house but [some] architects look at the costs and see us as too expensive or unapproachable. We’d like to see more co-operation between builders like us and architects.

When builders, engineers, architects and clients all understand what they are doing and why, most of those problems and extra costs will just disappear.

by Lloyd Alter

SOURCE: Treehugger