As more and more people live in densifying built environments, the importance of spending time outdoor encountering natural phenomena and learning to live closer to the seasonal cycles of the weather increases. The everyday experience of being connected to nature is a key factor in long-term health and well-being. Spending time outdoors also presents opportunities to meet other people and have shared encounters.

Everyone does not necessarily need to have their own garden, but they should have access to a range of outdoor spaces and experiences, from a window box to a roof terrace, from a balcony to a public park, from a sidewalk café to a tree-lined boulevard. These spaces can bring them closer to nature and help them live better with the weather.

Bringing Nature into the City

Biophilia is the affinity humans have to connect with nature. There are also many health benefits that come with encounters with nature. International research has demonstrated the healing benefits of seeing trees for hospital patients, and the Japanese practice of forest bathing is becoming well-known. There may not always be natural landscape close by to connect with, so the experience of nature, or at least strong elements of nature, may need to be brought into the city. There are many ways to bring greenery and water back into the urban environment. Although vegetation is probably the most important aspect of nature in improving the environment of urban places, the presence of water may be the most special. The strongest sensory experiences are associated with water, in particular running water, with sound, movement and reflection.

In Freiburg, small and shallow channels of water run through the streets of the medieval core, reinterpreting a historical system of small streams. These Bächle are 20-50 centimeters (8-20 inches) wide and 5-10 centimeters (2-4 inches) deep. The water channels have multiple functions: cooling and cleaning, acting as a separator between pedestrians and trams, or defining a zone for sitting and staying. They reflect a dancing light in the narrower, dark streets. Perhaps best of all, they turn the streets into a giant playground, offering children of all ages temptation and opportunities to sail small boats, paddle and splash about. This very small feature has significantly larger consequences, allowing the streets to do more by increasing the intensity of use. The Bächle help achieve the balance between recreation (staying, sitting and playing) and function (multi-modal traffic corridors).

In Freiburg, Germany, small, shallow streams called Bächle run

through the streets of the medieval old town. (Photo by David Sim)

How Street Trees Transform Urban Spaces

Planting street trees is one of the most significant things that can be done to improve an urban environment. Beyond their inherent beauty, street trees do many useful things that help improve the look, feel and performance of urban spaces. Trees change the climate of streets (and whole cities) by providing buildings and street surfaces with shade from the sun and protection from the wind. This makes it more pleasant to spend time outdoors on the sidewalk and easier to move about on foot and bicycle or wait for transit. In this way, trees have an important role in supporting active mobility.

More than a mere green surface, trees help reduce the heat-island effect, which blights many urban places, through shading, reflectance, evaporative cooling and evapotranspiration. Trees act as privacy screens in densely built areas. They filter strong sunlight, reducing glare and can act as light reflectors, throwing a dynamic “dancing” light into buildings. Trees provide a hugely significant sensory experience for people in streets with their sounds, smells and movements. Their ever-changing appearance gives people an awareness of the seasons and the passing of time, and effectively turn streets into linear parks.

Trees absorb carbon dioxide. Since cities produce most of the carbon dioxide, it makes sense to place trees at the source of the problem and where people are most vulnerable. Trees are natural air filters, capturing dust and other particles from the air by trapping them on their leaves and in their bark, as well as absorbing unpleasant smells and pollutant gases such as ammonia, sulphur and nitrogen oxides. This is particularly significant in relation to vehicle emissions.

Connecting to the Nature That is There

Almost every town or city has some natural amenity, whether it’s some kind of water, topography or views. The way a place connects to its natural amenities and works to accentuate the best features, however modest, can have a significant effect on how much time people spend outdoors. Supports can be put in place to encourage people to spend time outside and encounter nature, and can also extend their comfort zone, making the experience feel easy, desirable and pleasurable.

This could include orienting new buildings to allow views of nature, uncovering a natural stream or river, planting street trees allowing microhabitats to bloom or simply placing furniture outside of a café, allowing people to sit in the sun.

All of these encounters with nature, as grand as a view of mountains and as subtle as the sound of a birdsong, are significant and provide us with a strong awareness of the circle of life. Being aware of nature is the first step to understanding it, living with it and learning how to adapt to the environment.

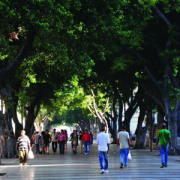

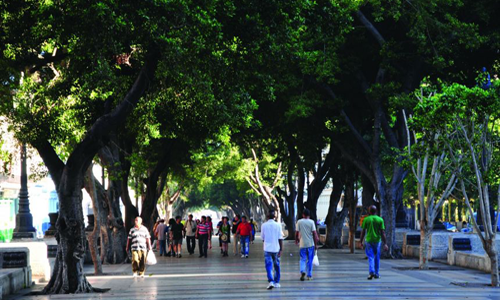

In Havana, street trees form a canopy that creates an outdoor room and softens

the climate for walking and lingering. (Photo by David Sim)

The simplest form of connecting people to nature is making what’s already there easily accessible. In Freiburg, Germany, the Dreisam River runs just outside the medieval core. In the summer months, people sit on rocks in the river and enjoy its cooling effect and the shade from the trees on the riverbank. The rocks make for an informal sitting landscape, offering encounters with people as well as with nature. Even a small water surface of a few centimeters/inches deep, such as the stream that flows through the center of Kyoto, Japan, can have a strong presence.

The huge significance and value of water has been recognized in cities like Århus in Denmark and the South Korean capital Seoul, both of which have gone to considerable lengths to reopen rivers previously hidden under road infrastructure. The results of these efforts have radically changed the behavior of the people and dramatically increased the amount of time spent outside.

An Outdoor Living Room for the Whole City: Västra Hamnen, Malmö, Sweden

The Swedish city of Malmö had historically turned its back to the sea, but with the redevelopment of the Western Harbor from industrial zone to residential neighborhood, the value of the waterfront was rediscovered. The flagship Bo01 housing exhibition introduced the Sundspromenad, a pedestrian waterfront, giving the area a resort-like feel. The pedestrian waterfront is probably the most important public space in the city.

The main feature is a multifunctional stepped wall, which functions as a storm barrier, a wind break, a seating landscape, a playground, a stage, a catwalk, a sunbathing deck and a viewing platform that marks and accentuates the spectacular view over the water toward the Öresund Bridge and Copenhagen.

Further along in the adjacent park, Daniaparken, enclosed, wind-protected areas afford a longer season of sitting outside and sunbathing while platforms, steps and ladders into the sea make sea-bathing easier. The removal of dangerous rocks on the seabed has made diving possible and the spectacular end of the promenade look-out point now doubles as a diving board.

At Västra Hamnen, in Malmö, Sweden, water features offer entertaining play

opportunities for children, while adults relax. (Photo by David Sim)

Sundspromenad and Daniaparken attract visitors from the immediate neighborhood, the larger city and even the surrounding region. Malmö has long stretches of beach, yet every day people of every age, ethnicity and socio-economic background come to the Sundspromenad, proving that an urban experience of nature can be just as attractive as a natural one.

Making the Most of Infrastructure: Taasinge Square, Copenhagen, Denmark

In recent years, Copenhagen has been hit by more frequent and more severe rainstorms, which have led to extreme flooding, causing extensive damage. In response to this new challenge, the City has developed a climate-adaptation plan, which calls for the creation of new soft landscaping in public places to absorb flooding.

Spaces that previously had hard, impervious surfaces are being landscaped to accommodate flood water and allow slower run-off during and after rainstorms. Instead of investing in expensive underground infrastructure that is invisible to citizens and unused most of the time, the City has leveraged the investment in stormwater management to create greater value. The 2011 plan includes “Cloud Burst Projects” for more than 300 parks, streets and squares to be implemented over the coming decades. The new landscapes improve the everyday quality of life for Copenhageners while increasing property values, increasing biodiversity and reducing the heat-island effect.

Being outside means having sensory experiences, actually feeling the weather on your skin. In order to get people who live their lives indoors to develop better relationships with the outdoors, to learn to live with the weather or become better neighbors with nature, we must offer options and opportunities, frequent invitations and occasional nudges, to move closer to nature, one step at a time.

One such new public space is Taasinge Square in Copenhagen’s first climate-resilient neighborhood, part of the City’s Climate Plan. The square that used to be covered in asphalt and parked cars has been transformed into a distinctive, green and sustainable landmark. The park’s response to stormwater is above-ground and therefore visible to everyone. The space promotes understanding of climate change in an active social context. When it’s not flooded, it’s a great recreational landscape for everyone to enjoy.

Repurposing Infrastructure as Public Space: Kizu River Waterfront Project, Osaka, Japan

The Japanese are accustomed to climatic disasters. Tsunamis, earthquakes, landslides, floods and volcanic eruptions are all regular events. Japan has invested in hardware (infrastructure) and software (training) to ensure the safety of its citizens. High flood-defense walls protect cities like Osaka from the risk of flooding, but the walls disconnect citizens from their living waterfront. The scale of the walls eliminates any communication with the water, and the citizens lose their awareness of the sea, forgetting both their fear of and their delight in the water.

Ryoko Iwase’s project from 2013-2017 repurposes the flood-defense wall, converting the hard, engineered infrastructure into public space, a terraced landscape with room for varied interpretation, inhabitation and appropriation by the users. There is a continuous footpath along the water’s edge to encourage people to walk by the water. There are big steps for sitting, inviting people to stay and watch the water. There is also a system of planters, which softens the concrete structure with vegetation. The citizens are invited to actively tend the greenery. By reimagining infrastructure as public space, people now have the opportunity to spend more time outdoors, connecting to the forces of nature both passively and actively.

River Swimming in Berne, Switzerland

Imagine leaving your crowded office or your tiny city apartment, hot and sweaty on a summer’s day, walking just a few hundred meters and then jumping straight into the cooling waters of a river. Swimming in the Aare River in Berne is an example of an activity that makes dense city life more enjoyable. It is the opportunity to connect, physically and mentally, to the natural environment in the middle of a city. The experience engages the senses: feeling your skin submerged in the water, putting your head underwater to hear the sounds of the stones on the river bed while hearing the splashing and voices of fellow swimmers and the sounds of birds and trees on the riverbank.

In Berne, Switzerland, swimming in the Aare River offers a new way to interact with neighbors: jump off a footbridge, let the current carry you downstream, then get out, walk back along the promenade and do it again. (Photo by David Sim)

In these exceptional circumstances, there is opportunity to meet and interact with your neighbors and fellow citizens. Since the current carries people downriver, there is a ritual of getting in at the concrete steps or jumping off a footbridge, swimming with the flow, then getting out, walking back along the promenade to where you started, and then doing it all over again.

It might seem like an unlikely activity for the reserved citizens of the Swiss capital, but this natural wonder brings people from all kinds of backgrounds together in extremely relaxed circumstances. The bankers and politicians shed their suits and enjoy the experience of meeting their neighbors in their swimming costumes. The river swimming brings a kind of holiday spirit to the everyday life of the city.

River swimming is free and it is socially inclusive for a diverse group of people—young and old, different nationalities and ethnicities, locals and tourists. Even some pets join in. Since this activity is easily accessible every day after school or after work, it means there are many and frequent opportunities to connect to nature and, at the same time, make new friends and acquaintances.

Beyond the daily enjoyment, the Aare River experience informs people’s broader understanding of the weather and the environment. For example, people better understand how the water temperature in the river is affected by the weather in the mountains, and take notice from year to year of the start, the end, the length and the consistency of the swimming season. These are relevant topics of conversation as this important annual activity is so directly affected by the weather. This feeds into a deeper understanding of the weather patterns, cycles and how it all connects to our own experiences and lives. Even for the spectator, swimming has a relevance, and the sight of river swimmers while sitting on a train or tram connects people to their place and climate.

The infrastructure that supports the river swimming is quite basic and intuitive to use. Along the riverside, there are simple concrete steps with brightly painted handrails to make getting in and out easy as well as buoys and some simple warning signs telling people when they should get out.

Living with the Weather

Living with the weather is about recognizing how the design of the built environment can influence our behavior, making it easy to move between inside and out, and making it comfortable to spend more time outdoors. At the same time, by taking small steps, we can move toward living more in harmony with the forces of nature in a time of climate change. Being outside means having sensory experiences, actually feeling the weather on your skin. In order to get people who live their lives indoors to develop better relationships with the outdoors, to learn to live with the weather or become better neighbors with nature, we must offer options and opportunities, frequent invitations and occasional nudges, to move closer to nature, one step at a time.

Popular Stories

Many newly built environments such as homes, institutions and workplaces seem to be oriented to staying indoors, and any mobility around them is based on driving. The internet age has spurred debate and research on the value of being outside and in contact with nature – especially related to the upbringing of children in an age of iPads. Spending time outdoors creates opportunities for socialization, for shared experiences of natural phenomena, which in turn can help build a common understanding and consensus of what’s happening with our climate.

Every city comes with its own set of climate challenges. But weather does not only have to be something that we endure. It is also possible to design outside conditions through designs to create better, simple details—such as the shape and massing of buildings and the spaces in between—that have the potential to create more comfortable microclimates. By letting the sun in, and sometimes keeping it out, by sheltering from the wind and rain, we have the potential to make our own weather or at least to extend the time we can spend outdoors. Low-tech, low-cost interventions such as shutters and stairs, balconies and arcades can bring people out of their normal, indoor comfort zones into a closer, more satisfying relationship with the natural and social environments outside.

There is a well-known saying in Scandinavia: “There is no such thing as bad weather, only the wrong clothes.”

An excerpt of “Soft City: Building Density for Everyday Life,” by David Sim, published by Island Press. The author makes a case for a human-scale “soft city” that prioritizes the organization and layout of the built environment for more fluid movement and comfort, a diversity of building types and thoughtful design to ensure a sustainable urban environment and society. In this excerpt, Sim illuminates how outdoor space can enhance the experience of a city’s geography and climate, invite the community into the public sphere and mitigate the effects of climate change.

Source: Next City